PDF Publication Title:

Text from PDF Page: 002

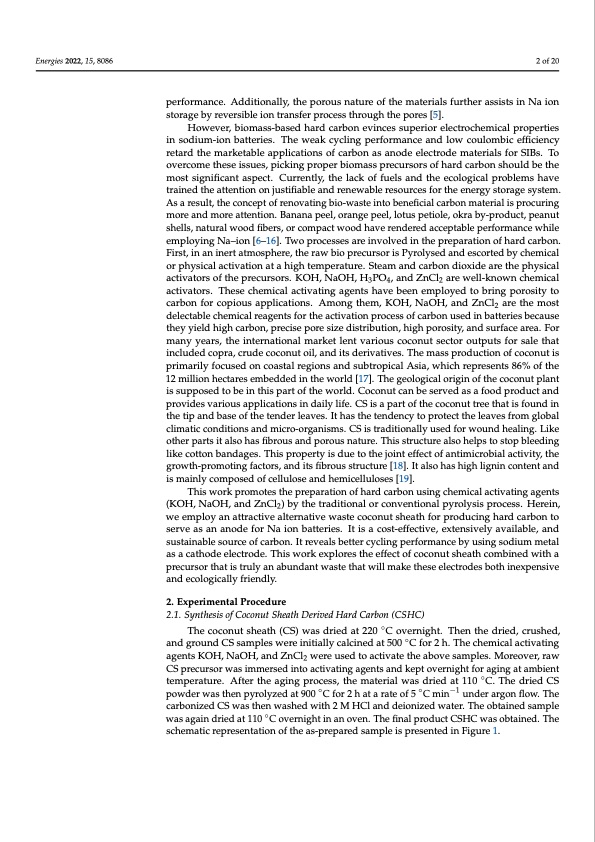

Energies 2022, 15, 8086 2 of 20 performance. Additionally, the porous nature of the materials further assists in Na ion storage by reversible ion transfer process through the pores [5]. However, biomass-based hard carbon evinces superior electrochemical properties in sodium-ion batteries. The weak cycling performance and low coulombic efficiency retard the marketable applications of carbon as anode electrode materials for SIBs. To overcome these issues, picking proper biomass precursors of hard carbon should be the most significant aspect. Currently, the lack of fuels and the ecological problems have trained the attention on justifiable and renewable resources for the energy storage system. As a result, the concept of renovating bio-waste into beneficial carbon material is procuring more and more attention. Banana peel, orange peel, lotus petiole, okra by-product, peanut shells, natural wood fibers, or compact wood have rendered acceptable performance while employing Na–ion [6–16]. Two processes are involved in the preparation of hard carbon. First, in an inert atmosphere, the raw bio precursor is Pyrolysed and escorted by chemical or physical activation at a high temperature. Steam and carbon dioxide are the physical activators of the precursors. KOH, NaOH, H3PO4, and ZnCl2 are well-known chemical activators. These chemical activating agents have been employed to bring porosity to carbon for copious applications. Among them, KOH, NaOH, and ZnCl2 are the most delectable chemical reagents for the activation process of carbon used in batteries because they yield high carbon, precise pore size distribution, high porosity, and surface area. For many years, the international market lent various coconut sector outputs for sale that included copra, crude coconut oil, and its derivatives. The mass production of coconut is primarily focused on coastal regions and subtropical Asia, which represents 86% of the 12 million hectares embedded in the world [17]. The geological origin of the coconut plant is supposed to be in this part of the world. Coconut can be served as a food product and provides various applications in daily life. CS is a part of the coconut tree that is found in the tip and base of the tender leaves. It has the tendency to protect the leaves from global climatic conditions and micro-organisms. CS is traditionally used for wound healing. Like other parts it also has fibrous and porous nature. This structure also helps to stop bleeding like cotton bandages. This property is due to the joint effect of antimicrobial activity, the growth-promoting factors, and its fibrous structure [18]. It also has high lignin content and is mainly composed of cellulose and hemicelluloses [19]. This work promotes the preparation of hard carbon using chemical activating agents (KOH, NaOH, and ZnCl2) by the traditional or conventional pyrolysis process. Herein, we employ an attractive alternative waste coconut sheath for producing hard carbon to serve as an anode for Na ion batteries. It is a cost-effective, extensively available, and sustainable source of carbon. It reveals better cycling performance by using sodium metal as a cathode electrode. This work explores the effect of coconut sheath combined with a precursor that is truly an abundant waste that will make these electrodes both inexpensive and ecologically friendly. 2. Experimental Procedure 2.1. Synthesis of Coconut Sheath Derived Hard Carbon (CSHC) The coconut sheath (CS) was dried at 220 ◦C overnight. Then the dried, crushed, and ground CS samples were initially calcined at 500 ◦C for 2 h. The chemical activating agents KOH, NaOH, and ZnCl2 were used to activate the above samples. Moreover, raw CS precursor was immersed into activating agents and kept overnight for aging at ambient temperature. After the aging process, the material was dried at 110 ◦C. The dried CS powder was then pyrolyzed at 900 ◦C for 2 h at a rate of 5 ◦C min−1 under argon flow. The carbonized CS was then washed with 2 M HCl and deionized water. The obtained sample was again dried at 110 ◦C overnight in an oven. The final product CSHC was obtained. The schematic representation of the as-prepared sample is presented in Figure 1.PDF Image | Morphology Derived Coconut Sheath for Sodium-Ion Battery

PDF Search Title:

Morphology Derived Coconut Sheath for Sodium-Ion BatteryOriginal File Name Searched:

energies-15-08086.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |