PDF Publication Title:

Text from PDF Page: 014

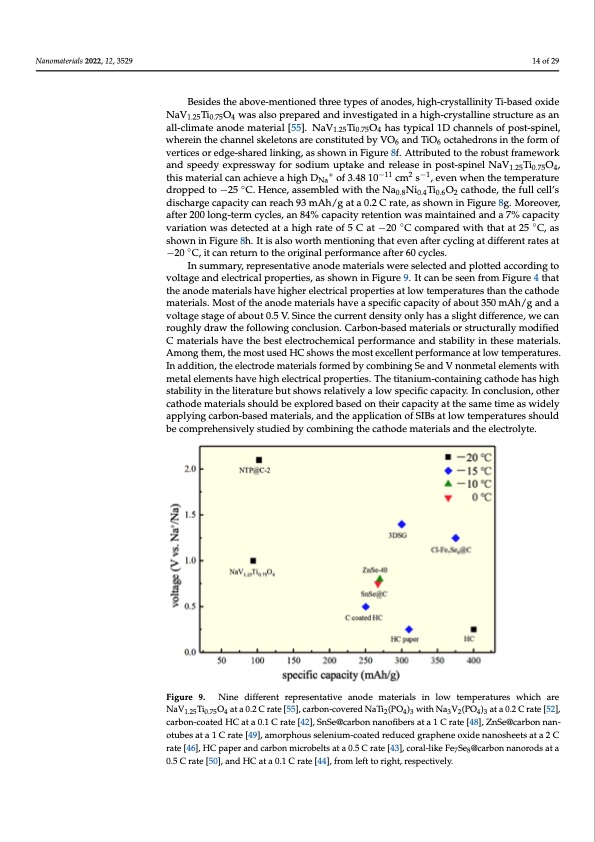

Nanomaterials 2022, 12, 3529 8h. It is also worth mentioning that even after cycling at different rates at −20 °C, it can return to the original performance after 60 cycles. In summary, representative anode materials were selected and plotted according t1o4 of 29 voltage and electrical properties, as shown in Figure 9. It can be seen from Figure 4 that the anode materials have higher electrical properties at low temperatures than the cathode materials. Most of the anode materials have a specific capacity of about 350 mAh/g and a Besides the above-mentioned three types of anodes, high-crystallinity Ti-based oxide voltage stage of about 0.5 V. Since the current density only has a slight difference, we can NaV1.25Ti0.75O4 was also prepared and investigated in a high-crystalline structure as an roughly draw the following conclusion. Carbon-based materials or structurally modified all-climate anode material [55]. NaV1.25Ti0.75O4 has typical 1D channels of post-spinel, C materials have the best electrochemical performance and stability in these materials. wherein the channel skeletons are constituted by VO6 and TiO6 octahedrons in the form of Amovnegrttichesmo,rtehdegme-oshstauresdedlinHkCingsh,oaswshtohwenmionsFtiegxucrell8efn.tAptterifbourtmedantocethaet lrowbutsetmfrpaemrae-work turesa.nIdn aspdedeitdioyne,xtphreeesslewctaryodfoermsoatdeiruiamls ufoprtmakeedabnydcroemlebaisneining Speosatn-sdpiVnenloNnmaVetal Telie- O , 1.25 0.75 4 mentshiwsimthamtereitallcealenmaecnhtiesvheavaehhigighhDelectroifca3l.4p8ro1p0ertiecsm. Thse ti,teavneiunmw-hcoentathineintegmcpaethra-ture Na+ −11 2−1 odehdarosphpigehdsttoab−il2it5yiCn.thHeelnitcer,aatussrembubltesdhowwitshrethlaetiNvealyaNliowTsipeOcificactahpoadceit,yt.hIenfcuolnl-cell’s ◦ 0.8 0.4 0.6 2 clusidoins,cohtahregrecatphaocditeymcantereialcshs9h3oumldAhb/egexaptlaor0e.2dCbarsaeted,oanssthoewirncaipnaFcigtyuraet8thge. Msaomreover, timeaafstewr2id0e0lyloanpgp-tleyrimngccyacrlbeos,na-bna8s4e%dmcaaptearciatyls,reatnednttihoenawpapslimcaationntaoinfeSdIBasnadtalo7w%tceamp-acity ◦◦ peravtuareiastsihonouwldasbedceotemcpterdehaetnasihvieglyhsrtautdeioedf 5byCcaotm−bi2n0ingCthcoemcaptahroedewmiathtertihaalst antd25theC, as electsrhoolywten. in Figure 8h. It is also worth mentioning that even after cycling at different rates at ◦ −A2m0onCg, iatllcathnereatbuorvnet-omtehnetiornigeidnalnpoedrefomrmataenricaelsa,fHteCr 6a0ncoydcelems.aterials are most val- + uedduetIontshuemirmloawry,proetpernetsiaenltvaetrisvuesaNnoad/eNmaatnedriahlisgwhecryeclsienlgecstteadbialnitdypdluortitnegddacec/soordin-gto voltage and electrical properties, as shown in Figure 9. It can be seen from Figure 4 that umization. The smooth electrochemical plateau of HC is attributed to the intercalation theanodematerialsha+vehigherelectricalpropertiesatlowtemperaturesthanthecathode and deintercalation of Na into graphite interlayer gap which is larger than 0.37 nm. HC, which has been widely used as a node material, also has higher stability and better elec- materials. Most of the anode materials have a specific capacity of about 350 mAh/g and a trochemical performance than other anode materials at low temperatures. The most im- voltage stage of about 0.5 V. Since the current density only has a slight difference, we can portant thing is that the precursor of HC is cheap and environmentally friendly, which roughly draw the following conclusion. Carbon-based materials or structurally modified has incomparable practical advantages compared to other anode materials. General HC C materials have the best electrochemical performance and stability in these materials. precursor materials are composed of various biopolymers, including hemicellulose, cellu- Among them, the most used HC shows the most excellent performance at low temperatures. lose, lignin, pectin, protein, free sugars, etc. In our article, both longan peel and tissue In addition, the electrode materials formed by combining Se and V nonmetal elements with metal elements have high electrical properties. The titanium-containing cathode has high paper used as precursor materials showed satisfactory low-temperature performance. The stability in the literature but shows relatively a low specific capacity. In conclusion, other main progress now lies in annealing the precursor and further improving the porosity cathode materials should be explored based on their capacity at the same time as widely inside the HC to increase the Na+ diffusion rate and improve its electrochemical perfor- applying carbon-based materials, and the application of SIBs at low temperatures should mance at low temperatures. be comprehensively studied by combining the cathode materials and the electrolyte. Figure 9. Nine different representative anode materials in low temperatures which are Figure 9. Nine different representative anode materials in low temperatures which are NaV1.25Ti0.75O4 at a 0.2 C rate [55], carbon-covered NaTi2(PO4)3 with Na3V2(PO4)3 at a 0.2 C rate [52], NaV1.25Ti0.75O4 at a 0.2 C rate [55], carbon-covered NaTi2(PO4)3 with Na3V2(PO4)3 at a 0.2 C rate [52], carbon-coated HC at a 0.1 C rate [42], SnSe@carbon nanofibers at a 1 C rate [48], ZnSe@carbon nan- otubes at a 1 C rate [49], amorphous selenium-coated reduced graphene oxide nanosheets at a 2 C rate [46], HC paper and carbon microbelts at a 0.5 C rate [43], coral-like Fe7Se8@carbon nanorods at a 0.5 C rate [50], and HC at a 0.1 C rate [44], from left to right, respectively.PDF Image | Na Ion Batteries Used at Low Temperatures

PDF Search Title:

Na Ion Batteries Used at Low TemperaturesOriginal File Name Searched:

nanomaterials-12-03529-v4.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |