PDF Publication Title:

Text from PDF Page: 005

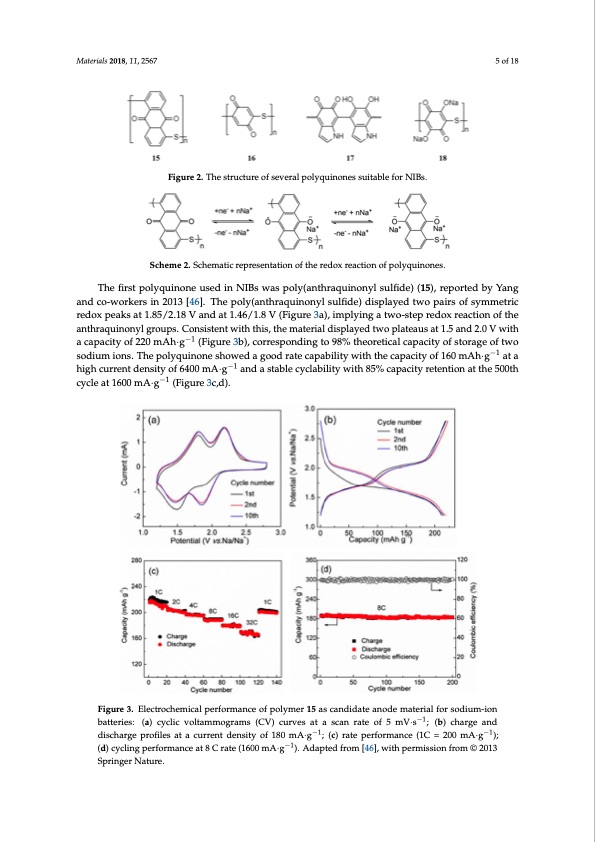

Materials 2018, 11, x FOR PEER REVIEW Materials 2018, 11, x FOR PEER REVIEW Materials 2018, 11, 2567 Materials 2018, 11, x FOR PEER REVIEW Figure 2. The structure of several polyquinones suitable for NIBs. Figure 2. The structure of several polyquinones suitable for NIBs. 5 of 20 5 of 20 5 of 18 5 of 20 2). 2). Figure 2. The structure of several polyquinones suitable for NIBs. Figure 2. The structure of several polyquinones suitable for NIBs. Similar to polyimides, polyquinones usually undergo two‐electron redox reactions through Similar to polyimides, polyquinones usually undergo two‐electron redox reactions through reversible electrochemical association of sodium ions with its redox‐active quinonyl groups (Scheme reversible electrochemical association of sodium ions with its redox‐active quinonyl groups (Scheme Similar to polyimides, polyquinones usually undergo two‐electron redox reactions through reversible electrochemical association of sodium ions with its redox‐active quinonyl groups (Scheme 2). ScShcehmemee2.2S. Schcheemaatitcicrreeprreessentation of theredoxrreaaccttioionnooffppoolylyqquuinionnoense.s. Scheme 2. Schematic representation of the redox reaction of polyquinones. TThheefifrisrsttpollyquinoneusseedininNNIBIBsswwasapsoplyo(layn(tahnrtahqruaiqnuoinyolnsyulfsiduel)fi(d1e5),(r1e5p)o,rtepdobryteYdabnygaYnadng The first polyquinone used in NIBs was poly(anthraquinonyl sulfide) (15), reported by Yang and ancdo‐wco-rwkeorskeinrs2i0n1320[4163].[4T6h]e. pTohley(panotlhyr(aqnuthinroanqyulinsounlfyidles)udlfiisdpela)ydeidsptlwayoepdatirwsoofpasyirmsmofetsryicmrmedeotrxic co‐workers in 2013 [46]. The poly(anthraquinonyl sulfide) displayed two pairs of symmetric redox peaks at 1.85/2.18 V and at 1.46/1.8 V (Figure 3a), implying a two‐step redox reaction of the redox peaks at 1.85/2.18 V and at 1.46/1.8 V (Figure 3a), implying a two-step redox reaction of the Scheme 2. Schematic representation of the redox reaction of polyquinones. peaks at 1.85/2.18 V and at 1.46/1.8 V (Figure 3a), implying a two‐step redox reaction of the anthraquinonyl groups. Consistent with this, the material displayed two plateaus at 1.5 and 2.0 V with anthraquinonyl groups. Consistent with this, the material displayed two plateaus at 1.5 and 2.0 V with anthraquinonyl groups. C‐1onsistent with this, the material displayed two plateaus at 1.5 and 2.0 V with a capacity of 220 mAhꞏ−g1 (Figure 3b), corresponding to 98% theoretical capacity of storage of two a capacTihtye foifrs2t2p0omlyqAuhin·gone (uFsiegdurine N3bI)B,scworarsesppoolyn(daninthgratoqu9i8n%ontyhlesourlefitdicea)l(c1a5p),arceiptyorotefdstboyraYgaenogfatnwdo a capacity of 220 mAhꞏg‐1 (Figure 3b), corresponding to 98% theoretical capacity of stora‐g1 e of two sodium ions. The polyquinone showed a good rate capability with the capacity of 160 mAhꞏg at a−h1igh co‐workers in 2013 [46]. The poly(anthraquinonyl sulfide) displayed two pairs of symmetric redox sodium ions. The polyquinone showed a good rate capability with the capacity of 160 mAh·g at a sodium ions. The polyquinon‐e1 showed a good rate capability with the capacity of 160 mAhꞏg‐1 at a high current density of 6400 mAꞏg and−a1 stable cyclability with 85% capacity retention at the 500th cycle at peaks at 1.85/2.18 V and at 1.46/1.8 V (Figure 3a), implying a two‐step redox reaction of the high current density of 6400 mA·g and a stable cyclability with 85% capacity retention at the 500th current den‐1sity of 6400 mAꞏg‐1 and a stable cyclability with 85% capacity retention at the 500th cycle at 1600 mAꞏg (Figures 3 c,d). anthraquinonyl gr−o1ups. Consistent with this, the material displayed two plateaus at 1.5 and 2.0 V with cycle at 1600 mA·g (Figure 3c,d). 1600 mAꞏg‐1 (Figures 3 c,d). a capacity of 220 mAhꞏg‐1 (Figure 3b), corresponding to 98% theoretical capacity of storage of two sodium at a high current h cycle at 1600 mA Figure 3. Electrochemical performance of polymer 15 as candidate anode material for sodium-ion batteries: (a) cyclic voltammograms (CV) curves at a scan rate of 5 mV·s−1; (b) charge and discharge profiles at a current density of 180 mA·g−1; (c) rate performance (1C = 200 mA·g−1); (d) cycling performance at 8 C rate (1600 mA·g−1). Adapted from [46], with permission from © 2013 Springer Nature. ions. The polyquinone showed a good rate capability with the capacity of 160 mAhꞏg‐1 density of 6400 mAꞏg‐1 and a stable cyclability with 85% capacity retention at the 500t ꞏg‐1 (Figures 3 c,d).PDF Image | Polymer Electrode Materials for Sodium-ion Batteries

PDF Search Title:

Polymer Electrode Materials for Sodium-ion BatteriesOriginal File Name Searched:

materials-11-02567.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |