PDF Publication Title:

Text from PDF Page: 002

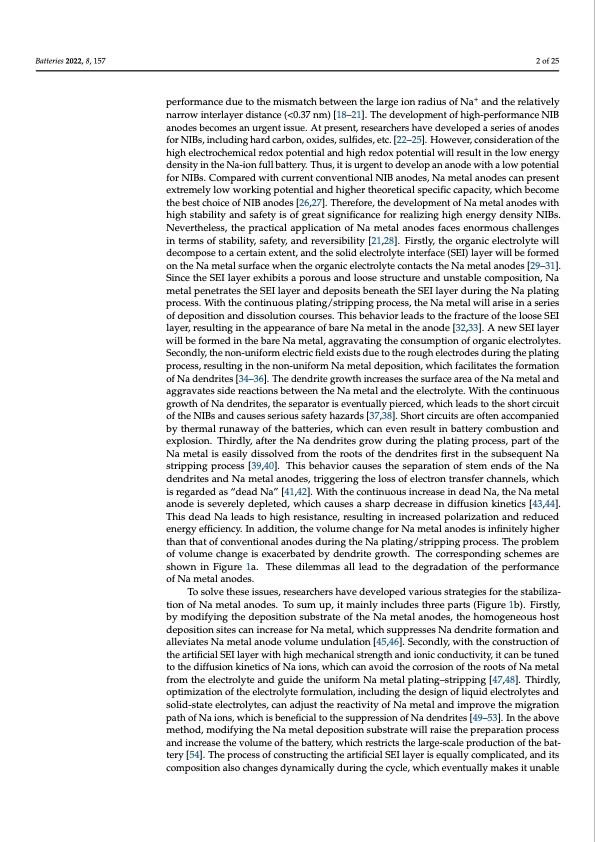

Batteries 2022, 8, 157 2 of 25 performance due to the mismatch between the large ion radius of Na+ and the relatively narrow interlayer distance (<0.37 nm) [18–21]. The development of high-performance NIB anodes becomes an urgent issue. At present, researchers have developed a series of anodes for NIBs, including hard carbon, oxides, sulfides, etc. [22–25]. However, consideration of the high electrochemical redox potential and high redox potential will result in the low energy density in the Na-ion full battery. Thus, it is urgent to develop an anode with a low potential for NIBs. Compared with current conventional NIB anodes, Na metal anodes can present extremely low working potential and higher theoretical specific capacity, which become the best choice of NIB anodes [26,27]. Therefore, the development of Na metal anodes with high stability and safety is of great significance for realizing high energy density NIBs. Nevertheless, the practical application of Na metal anodes faces enormous challenges in terms of stability, safety, and reversibility [21,28]. Firstly, the organic electrolyte will decompose to a certain extent, and the solid electrolyte interface (SEI) layer will be formed on the Na metal surface when the organic electrolyte contacts the Na metal anodes [29–31]. Since the SEI layer exhibits a porous and loose structure and unstable composition, Na metal penetrates the SEI layer and deposits beneath the SEI layer during the Na plating process. With the continuous plating/stripping process, the Na metal will arise in a series of deposition and dissolution courses. This behavior leads to the fracture of the loose SEI layer, resulting in the appearance of bare Na metal in the anode [32,33]. A new SEI layer will be formed in the bare Na metal, aggravating the consumption of organic electrolytes. Secondly, the non-uniform electric field exists due to the rough electrodes during the plating process, resulting in the non-uniform Na metal deposition, which facilitates the formation of Na dendrites [34–36]. The dendrite growth increases the surface area of the Na metal and aggravates side reactions between the Na metal and the electrolyte. With the continuous growth of Na dendrites, the separator is eventually pierced, which leads to the short circuit of the NIBs and causes serious safety hazards [37,38]. Short circuits are often accompanied by thermal runaway of the batteries, which can even result in battery combustion and explosion. Thirdly, after the Na dendrites grow during the plating process, part of the Na metal is easily dissolved from the roots of the dendrites first in the subsequent Na stripping process [39,40]. This behavior causes the separation of stem ends of the Na dendrites and Na metal anodes, triggering the loss of electron transfer channels, which is regarded as “dead Na” [41,42]. With the continuous increase in dead Na, the Na metal anode is severely depleted, which causes a sharp decrease in diffusion kinetics [43,44]. This dead Na leads to high resistance, resulting in increased polarization and reduced energy efficiency. In addition, the volume change for Na metal anodes is infinitely higher than that of conventional anodes during the Na plating/stripping process. The problem of volume change is exacerbated by dendrite growth. The corresponding schemes are shown in Figure 1a. These dilemmas all lead to the degradation of the performance of Na metal anodes. To solve these issues, researchers have developed various strategies for the stabiliza- tion of Na metal anodes. To sum up, it mainly includes three parts (Figure 1b). Firstly, by modifying the deposition substrate of the Na metal anodes, the homogeneous host deposition sites can increase for Na metal, which suppresses Na dendrite formation and alleviates Na metal anode volume undulation [45,46]. Secondly, with the construction of the artificial SEI layer with high mechanical strength and ionic conductivity, it can be tuned to the diffusion kinetics of Na ions, which can avoid the corrosion of the roots of Na metal from the electrolyte and guide the uniform Na metal plating–stripping [47,48]. Thirdly, optimization of the electrolyte formulation, including the design of liquid electrolytes and solid-state electrolytes, can adjust the reactivity of Na metal and improve the migration path of Na ions, which is beneficial to the suppression of Na dendrites [49–53]. In the above method, modifying the Na metal deposition substrate will raise the preparation process and increase the volume of the battery, which restricts the large-scale production of the bat- tery [54]. The process of constructing the artificial SEI layer is equally complicated, and its composition also changes dynamically during the cycle, which eventually makes it unablePDF Image | Recent Development for Sodium Metal Batteries

PDF Search Title:

Recent Development for Sodium Metal BatteriesOriginal File Name Searched:

batteries-08-00157-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |