PDF Publication Title:

Text from PDF Page: 003

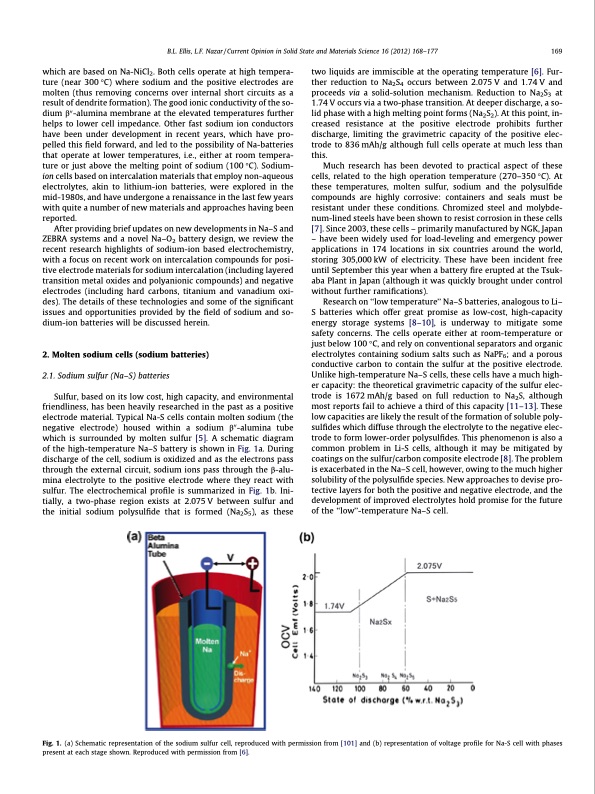

B.L. Ellis, L.F. Nazar / Current Opinion in Solid State and Materials Science 16 (2012) 168–177 169 which are based on Na-NiCl2. Both cells operate at high tempera- ture (near 300 °C) where sodium and the positive electrodes are molten (thus removing concerns over internal short circuits as a result of dendrite formation). The good ionic conductivity of the so- dium b00-alumina membrane at the elevated temperatures further helps to lower cell impedance. Other fast sodium ion conductors have been under development in recent years, which have pro- pelled this field forward, and led to the possibility of Na-batteries that operate at lower temperatures, i.e., either at room tempera- ture or just above the melting point of sodium (100 °C). Sodium- ion cells based on intercalation materials that employ non-aqueous electrolytes, akin to lithium-ion batteries, were explored in the mid-1980s, and have undergone a renaissance in the last few years with quite a number of new materials and approaches having been reported. After providing brief updates on new developments in Na–S and ZEBRA systems and a novel Na–O2 battery design, we review the recent research highlights of sodium-ion based electrochemistry, with a focus on recent work on intercalation compounds for posi- tive electrode materials for sodium intercalation (including layered transition metal oxides and polyanionic compounds) and negative electrodes (including hard carbons, titanium and vanadium oxi- des). The details of these technologies and some of the significant issues and opportunities provided by the field of sodium and so- dium-ion batteries will be discussed herein. 2. Molten sodium cells (sodium batteries) 2.1. Sodium sulfur (Na–S) batteries Sulfur, based on its low cost, high capacity, and environmental friendliness, has been heavily researched in the past as a positive electrode material. Typical Na-S cells contain molten sodium (the negative electrode) housed within a sodium b00-alumina tube which is surrounded by molten sulfur [5]. A schematic diagram of the high-temperature Na–S battery is shown in Fig. 1a. During discharge of the cell, sodium is oxidized and as the electrons pass through the external circuit, sodium ions pass through the b-alu- mina electrolyte to the positive electrode where they react with sulfur. The electrochemical profile is summarized in Fig. 1b. Ini- tially, a two-phase region exists at 2.075 V between sulfur and the initial sodium polysulfide that is formed (Na2S5), as these two liquids are immiscible at the operating temperature [6]. Fur- ther reduction to Na2S4 occurs between 2.075 V and 1.74 V and proceeds via a solid-solution mechanism. Reduction to Na2S3 at 1.74 V occurs via a two-phase transition. At deeper discharge, a so- lid phase with a high melting point forms (Na2S2). At this point, in- creased resistance at the positive electrode prohibits further discharge, limiting the gravimetric capacity of the positive elec- trode to 836 mAh/g although full cells operate at much less than this. Much research has been devoted to practical aspect of these cells, related to the high operation temperature (270–350 °C). At these temperatures, molten sulfur, sodium and the polysulfide compounds are highly corrosive: containers and seals must be resistant under these conditions. Chromized steel and molybde- num-lined steels have been shown to resist corrosion in these cells [7]. Since 2003, these cells – primarily manufactured by NGK, Japan – have been widely used for load-leveling and emergency power applications in 174 locations in six countries around the world, storing 305,000 kW of electricity. These have been incident free until September this year when a battery fire erupted at the Tsuk- aba Plant in Japan (although it was quickly brought under control without further ramifications). Research on ‘‘low temperature’’ Na–S batteries, analogous to Li– S batteries which offer great promise as low-cost, high-capacity energy storage systems [8–10], is underway to mitigate some safety concerns. The cells operate either at room-temperature or just below 100 °C, and rely on conventional separators and organic electrolytes containing sodium salts such as NaPF6; and a porous conductive carbon to contain the sulfur at the positive electrode. Unlike high-temperature Na–S cells, these cells have a much high- er capacity: the theoretical gravimetric capacity of the sulfur elec- trode is 1672 mAh/g based on full reduction to Na2S, although most reports fail to achieve a third of this capacity [11–13]. These low capacities are likely the result of the formation of soluble poly- sulfides which diffuse through the electrolyte to the negative elec- trode to form lower-order polysulfides. This phenomenon is also a common problem in Li-S cells, although it may be mitigated by coatings on the sulfur/carbon composite electrode [8]. The problem is exacerbated in the Na–S cell, however, owing to the much higher solubility of the polysulfide species. New approaches to devise pro- tective layers for both the positive and negative electrode, and the development of improved electrolytes hold promise for the future of the ‘‘low’’-temperature Na–S cell. Fig. 1. (a) Schematic representation of the sodium sulfur cell, reproduced with permission from [101] and (b) representation of voltage profile for Na-S cell with phases present at each stage shown. Reproduced with permission from [6].PDF Image | Sodium and sodium-ion energy storage batteries

PDF Search Title:

Sodium and sodium-ion energy storage batteriesOriginal File Name Searched:

2012_Na-battery_review.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |