PDF Publication Title:

Text from PDF Page: 002

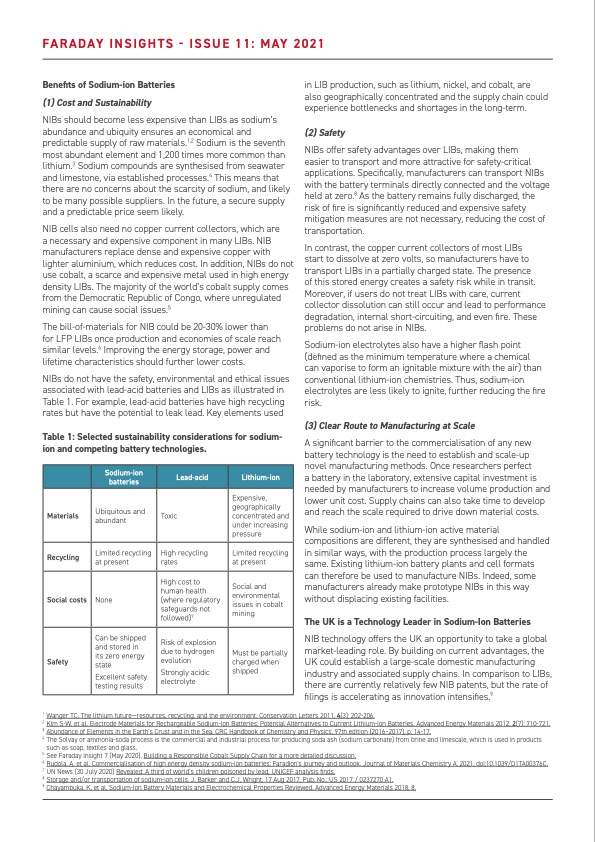

FARADAY INSIGHTS - ISSUE 11: MAY 2021 Benefits of Sodium-ion Batteries (1) Cost and Sustainability NIBs should become less expensive than LIBs as sodium’s abundance and ubiquity ensures an economical and predictable supply of raw materials.1,2 Sodium is the seventh most abundant element and 1,200 times more common than lithium.3 Sodium compounds are synthesised from seawater and limestone, via established processes.4 This means that there are no concerns about the scarcity of sodium, and likely to be many possible suppliers. In the future, a secure supply and a predictable price seem likely. NIB cells also need no copper current collectors, which are a necessary and expensive component in many LIBs. NIB manufacturers replace dense and expensive copper with lighter aluminium, which reduces cost. In addition, NIBs do not use cobalt, a scarce and expensive metal used in high energy density LIBs. The majority of the world’s cobalt supply comes from the Democratic Republic of Congo, where unregulated mining can cause social issues.5 The bill-of-materials for NIB could be 20-30% lower than for LFP LIBs once production and economies of scale reach similar levels.6 Improving the energy storage, power and lifetime characteristics should further lower costs. NIBs do not have the safety, environmental and ethical issues associated with lead-acid batteries and LIBs as illustrated in Table 1. For example, lead-acid batteries have high recycling rates but have the potential to leak lead. Key elements used Table 1: Selected sustainability considerations for sodium- ion and competing battery technologies. in LIB production, such as lithium, nickel, and cobalt, are also geographically concentrated and the supply chain could experience bottlenecks and shortages in the long-term. (2) Safety NIBs offer safety advantages over LIBs, making them easier to transport and more attractive for safety-critical applications. Specifically, manufacturers can transport NIBs with the battery terminals directly connected and the voltage held at zero.8 As the battery remains fully discharged, the risk of fire is significantly reduced and expensive safety mitigation measures are not necessary, reducing the cost of transportation. In contrast, the copper current collectors of most LIBs start to dissolve at zero volts, so manufacturers have to transport LIBs in a partially charged state. The presence of this stored energy creates a safety risk while in transit. Moreover, if users do not treat LIBs with care, current collector dissolution can still occur and lead to performance degradation, internal short-circuiting, and even fire. These problems do not arise in NIBs. Sodium-ion electrolytes also have a higher flash point (defined as the minimum temperature where a chemical can vaporise to form an ignitable mixture with the air) than conventional lithium-ion chemistries. Thus, sodium-ion electrolytes are less likely to ignite, further reducing the fire risk. (3) Clear Route to Manufacturing at Scale A significant barrier to the commercialisation of any new battery technology is the need to establish and scale-up novel manufacturing methods. Once researchers perfect a battery in the laboratory, extensive capital investment is needed by manufacturers to increase volume production and lower unit cost. Supply chains can also take time to develop and reach the scale required to drive down material costs. While sodium-ion and lithium-ion active material compositions are different, they are synthesised and handled in similar ways, with the production process largely the same. Existing lithium-ion battery plants and cell formats can therefore be used to manufacture NIBs. Indeed, some manufacturers already make prototype NIBs in this way without displacing existing facilities. The UK is a Technology Leader in Sodium-Ion Batteries NIB technology offers the UK an opportunity to take a global market-leading role. By building on current advantages, the UK could establish a large-scale domestic manufacturing industry and associated supply chains. In comparison to LIBs, there are currently relatively few NIB patents, but the rate of filings is accelerating as innovation intensifies.9 Sodium-ion batteries Lead-acid Lithium-ion Materials Ubiquitous and abundant Toxic Expensive, geographically concentrated and under increasing pressure Recycling Limited recycling at present High recycling rates Limited recycling at present Social costs None High cost to human health (where regulatory safeguards not followed)7 Social and environmental issues in cobalt mining Safety Can be shipped and stored in its zero energy state Excellent safety testing results Risk of explosion due to hydrogen evolution Strongly acidic electrolyte Must be partially charged when shipped 1 Wanger TC. The lithium future—resources, recycling, and the environment. Conservation Letters 2011, 4(3): 202-206. 2 Kim S-W. et al. Electrode Materials for Rechargeable Sodium-Ion Batteries: Potential Alternatives to Current Lithium-Ion Batteries. Advanced Energy Materials 2012, 2(7): 710-721. 3 Abundance of Elements in the Earth’s Crust and in the Sea, CRC Handbook of Chemistry and Physics, 97th edition (2016–2017), p. 14-17. 4 The Solvay or ammonia-soda process is the commercial and industrial process for producing soda ash (sodium carbonate) from brine and limescale, which is used in products such as soap, textiles and glass. 5 See Faraday Insight 7 (May 2020), Building a Responsible Cobalt Supply Chain for a more detailed discussion. 6 Rudola, A. et al. Commercialisation of high energy density sodium-ion batteries: Faradion's journey and outlook. Journal of Materials Chemistry A, 2021, doi:10.1039/D1TA00376C. 7 UN News (30 July 2020) Revealed: A third of world’s children poisoned by lead, UNICEF analysis finds. 8 Storage and/or transportation of sodium-ion cells, J. Barker and C.J. Wright, 17 Aug 2017, Pub. No.: US 2017 / 0237270 A1. 9 Chayambuka, K. et al, Sodium‐Ion Battery Materials and Electrochemical Properties Reviewed. Advanced Energy Materials 2018, 8.PDF Image | Sodium-ion Batteries: Inexpensive and Sustainable Storage

PDF Search Title:

Sodium-ion Batteries: Inexpensive and Sustainable StorageOriginal File Name Searched:

Faraday_Insights_11_FINAL.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |