PDF Publication Title:

Text from PDF Page: 003

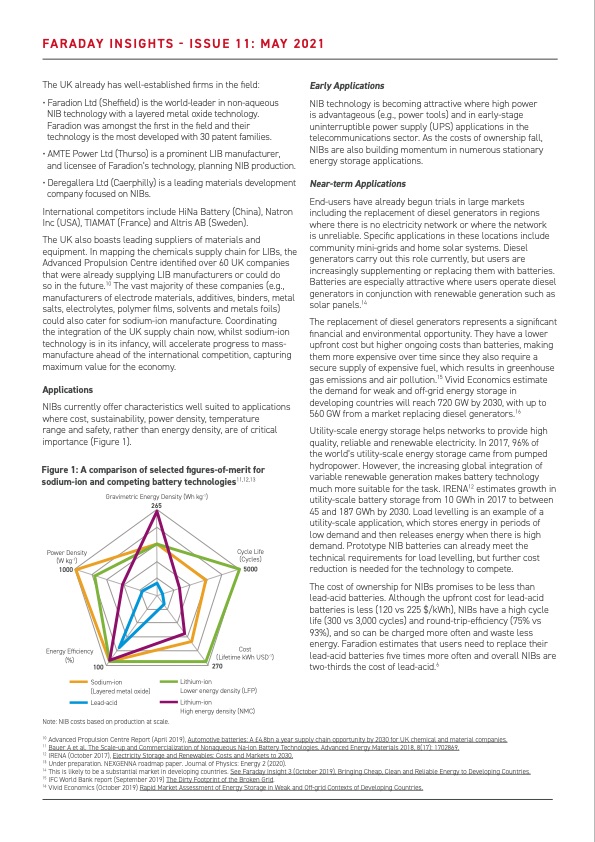

FARADAY INSIGHTS - ISSUE 11: MAY 2021 The UK already has well-established firms in the field: • Faradion Ltd (Sheffield) is the world-leader in non-aqueous NIB technology with a layered metal oxide technology. Faradion was amongst the first in the field and their technology is the most developed with 30 patent families. • AMTE Power Ltd (Thurso) is a prominent LIB manufacturer, and licensee of Faradion’s technology, planning NIB production. • Deregallera Ltd (Caerphilly) is a leading materials development company focused on NIBs. International competitors include HiNa Battery (China), Natron Inc (USA), TIAMAT (France) and Altris AB (Sweden). The UK also boasts leading suppliers of materials and equipment. In mapping the chemicals supply chain for LIBs, the Advanced Propulsion Centre identified over 60 UK companies that were already supplying LIB manufacturers or could do so in the future.10 The vast majority of these companies (e.g., manufacturers of electrode materials, additives, binders, metal salts, electrolytes, polymer films, solvents and metals foils) could also cater for sodium-ion manufacture. Coordinating the integration of the UK supply chain now, whilst sodium-ion technology is in its infancy, will accelerate progress to mass- manufacture ahead of the international competition, capturing maximum value for the economy. Applications NIBs currently offer characteristics well suited to applications where cost, sustainability, power density, temperature range and safety, rather than energy density, are of critical importance (Figure 1). Figure 1: A comparison of selected figures-of-merit for sodium-ion and competing battery technologies11,12,13 Early Applications NIB technology is becoming attractive where high power is advantageous (e.g., power tools) and in early-stage uninterruptible power supply (UPS) applications in the telecommunications sector. As the costs of ownership fall, NIBs are also building momentum in numerous stationary energy storage applications. Near-term Applications End-users have already begun trials in large markets including the replacement of diesel generators in regions where there is no electricity network or where the network is unreliable. Specific applications in these locations include community mini-grids and home solar systems. Diesel generators carry out this role currently, but users are increasingly supplementing or replacing them with batteries. Batteries are especially attractive where users operate diesel generators in conjunction with renewable generation such as solar panels.14 The replacement of diesel generators represents a significant financial and environmental opportunity. They have a lower upfront cost but higher ongoing costs than batteries, making them more expensive over time since they also require a secure supply of expensive fuel, which results in greenhouse gas emissions and air pollution.15 Vivid Economics estimate the demand for weak and off-grid energy storage in developing countries will reach 720 GW by 2030, with up to 560 GW from a market replacing diesel generators.16 Utility-scale energy storage helps networks to provide high quality, reliable and renewable electricity. In 2017, 96% of the world’s utility-scale energy storage came from pumped hydropower. However, the increasing global integration of variable renewable generation makes battery technology much more suitable for the task. IRENA12 estimates growth in utility-scale battery storage from 10 GWh in 2017 to between 45 and 187 GWh by 2030. Load levelling is an example of a utility-scale application, which stores energy in periods of low demand and then releases energy when there is high demand. Prototype NIB batteries can already meet the technical requirements for load levelling, but further cost reduction is needed for the technology to compete. The cost of ownership for NIBs promises to be less than lead-acid batteries. Although the upfront cost for lead-acid batteries is less (120 vs 225 $/kWh), NIBs have a high cycle life (300 vs 3,000 cycles) and round-trip-efficiency (75% vs 93%), and so can be charged more often and waste less energy. Faradion estimates that users need to replace their lead-acid batteries five times more often and overall NIBs are two-thirds the cost of lead-acid.6 Gravimetric Energy Density (Wh kg-1) 265 Power Density (W kg-1) 1000 Energy Efficiency (%) 100 Sodium-ion (Layered metal oxide) Lead-acid Cycle Life (Cycles) 5000 Cost (Lifetime kWh USD-1) 270 Note: NIB costs based on production at scale. Lithium-ion Lower energy density (LFP) Lithium-ion High energy density (NMC) 10 Advanced Propulsion Centre Report (April 2019), Automotive batteries: A £4.8bn a year supply chain opportunity by 2030 for UK chemical and material companies. 11 Bauer A et al. The Scale-up and Commercialization of Nonaqueous Na-Ion Battery Technologies. Advanced Energy Materials 2018, 8(17): 1702869. 12 IRENA (October 2017), Electricity Storage and Renewables: Costs and Markets to 2030. 13 Under preparation. NEXGENNA roadmap paper. Journal of Physics: Energy 2 (2020). 14 This is likely to be a substantial market in developing countries. See Faraday Insight 3 (October 2019), Bringing Cheap, Clean and Reliable Energy to Developing Countries. 15 IFC World Bank report (September 2019) The Dirty Footprint of the Broken Grid. 16 Vivid Economics (October 2019) Rapid Market Assessment of Energy Storage in Weak and Off-grid Contexts of Developing Countries.PDF Image | Sodium-ion Batteries: Inexpensive and Sustainable Storage

PDF Search Title:

Sodium-ion Batteries: Inexpensive and Sustainable StorageOriginal File Name Searched:

Faraday_Insights_11_FINAL.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |