PDF Publication Title:

Text from PDF Page: 057

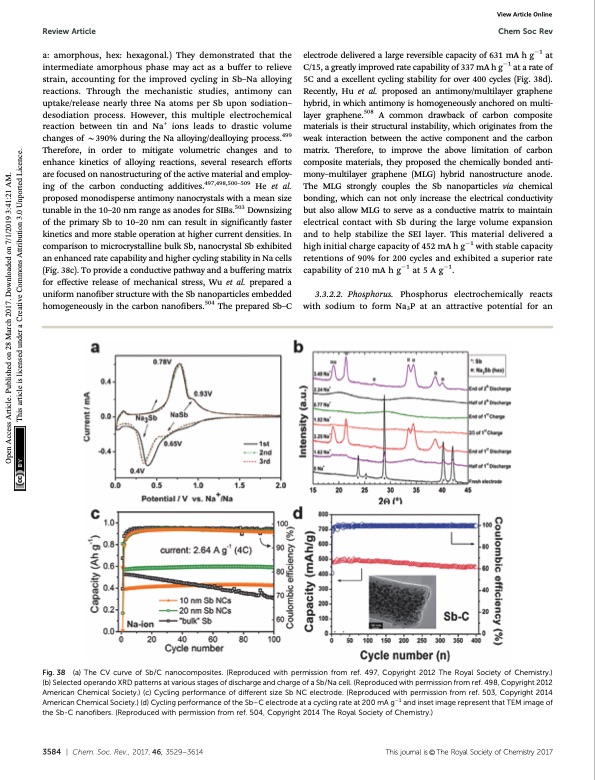

Review Article Chem Soc Rev electrode delivered a large reversible capacity of 631 mA h g1 at C/15, a greatly improved rate capability of 337 mA h g1 at a rate of 5C and a excellent cycling stability for over 400 cycles (Fig. 38d). Recently, Hu et al. proposed an antimony/multilayer graphene hybrid, in which antimony is homogeneously anchored on multi- layer graphene.508 A common drawback of carbon composite materials is their structural instability, which originates from the weak interaction between the active component and the carbon matrix. Therefore, to improve the above limitation of carbon composite materials, they proposed the chemically bonded anti- mony–multilayer graphene (MLG) hybrid nanostructure anode. The MLG strongly couples the Sb nanoparticles via chemical bonding, which can not only increase the electrical conductivity but also allow MLG to serve as a conductive matrix to maintain electrical contact with Sb during the large volume expansion and to help stabilize the SEI layer. This material delivered a high initial charge capacity of 452 mA h g1 with stable capacity retentions of 90% for 200 cycles and exhibited a superior rate capability of 210 mA h g1 at 5 A g1. 3.3.2.2. Phosphorus. Phosphorus electrochemically reacts with sodium to form Na3P at an attractive potential for an a: amorphous, hex: hexagonal.) They demonstrated that the intermediate amorphous phase may act as a buffer to relieve strain, accounting for the improved cycling in Sb–Na alloying reactions. Through the mechanistic studies, antimony can uptake/release nearly three Na atoms per Sb upon sodiation– desodiation process. However, this multiple electrochemical reaction between tin and Na+ ions leads to drastic volume changes of B390% during the Na alloying/dealloying process.499 Therefore, in order to mitigate volumetric changes and to enhance kinetics of alloying reactions, several research efforts are focused on nanostructuring of the active material and employ- ing of the carbon conducting additives.497,498,500–509 He et al. proposed monodisperse antimony nanocrystals with a mean size tunable in the 10–20 nm range as anodes for SIBs.503 Downsizing of the primary Sb to 10–20 nm can result in significantly faster kinetics and more stable operation at higher current densities. In comparison to microcrystalline bulk Sb, nanocrystal Sb exhibited an enhanced rate capability and higher cycling stability in Na cells (Fig. 38c). To provide a conductive pathway and a buffering matrix for effective release of mechanical stress, Wu et al. prepared a uniform nanofiber structure with the Sb nanoparticles embedded homogeneously in the carbon nanofibers.504 The prepared Sb–C View Article Online Fig. 38 (a) The CV curve of Sb/C nanocomposites. (Reproduced with permission from ref. 497, Copyright 2012 The Royal Society of Chemistry.) (b) Selected operando XRD patterns at various stages of discharge and charge of a Sb/Na cell. (Reproduced with permission from ref. 498, Copyright 2012 American Chemical Society.) (c) Cycling performance of different size Sb NC electrode. (Reproduced with permission from ref. 503, Copyright 2014 American Chemical Society.) (d) Cycling performance of the Sb–C electrode at a cycling rate at 200 mA g1 and inset image represent that TEM image of the Sb-C nanofibers. (Reproduced with permission from ref. 504, Copyright 2014 The Royal Society of Chemistry.) 3584 | Chem. Soc. Rev., 2017, 46, 3529--3614 This journal is © The Royal Society of Chemistry 2017 Open Access Article. Published on 28 March 2017. Downloaded on 7/1/2019 3:41:21 AM. This article is licensed under a Creative Commons Attribution 3.0 Unported Licence.PDF Image | Sodium-ion batteries present and future

PDF Search Title:

Sodium-ion batteries present and futureOriginal File Name Searched:

Sodium-ion batteries present and future.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |