PDF Publication Title:

Text from PDF Page: 004

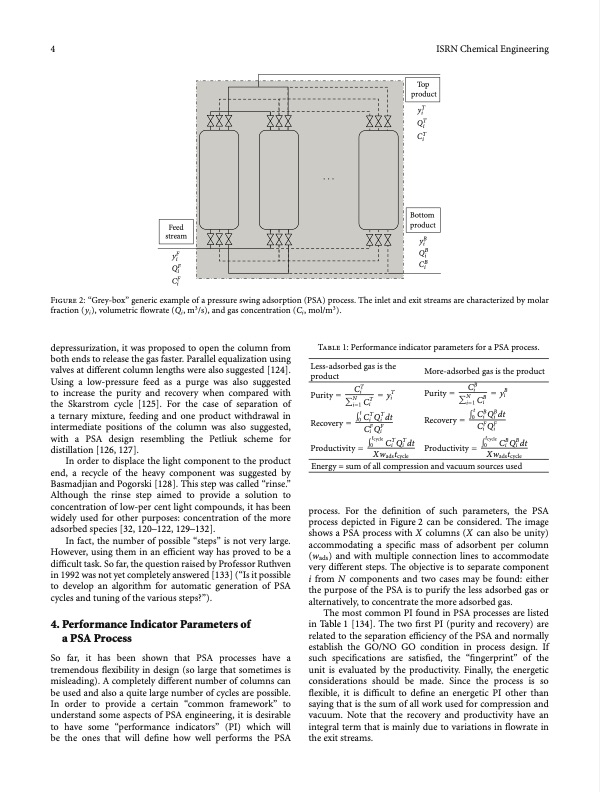

4 ISRN Chemical Engineering ··· Top product yiT QiT CiT Bottom product yiB QiB CiB Feed stream yiF QiF CiF Figure 2: “Grey-box” generic example of a pressure swing adsorption (PSA) process. The inlet and exit streams are characterized by molar fraction (yi), volumetric flowrate (Qi, m3/s), and gas concentration (Ci, mol/m3). depressurization, it was proposed to open the column from both ends to release the gas faster. Parallel equalization using valves at different column lengths were also suggested [124]. Using a low-pressure feed as a purge was also suggested to increase the purity and recovery when compared with the Skarstrom cycle [125]. For the case of separation of a ternary mixture, feeding and one product withdrawal in intermediate positions of the column was also suggested, with a PSA design resembling the Petliuk scheme for distillation [126, 127]. In order to displace the light component to the product end, a recycle of the heavy component was suggested by Basmadjian and Pogorski [128]. This step was called “rinse.” Although the rinse step aimed to provide a solution to concentration of low-per cent light compounds, it has been widely used for other purposes: concentration of the more adsorbed species [32, 120–122, 129–132]. In fact, the number of possible “steps” is not very large. However, using them in an efficient way has proved to be a difficult task. So far, the question raised by Professor Ruthven in 1992 was not yet completely answered [133] (“Is it possible to develop an algorithm for automatic generation of PSA cycles and tuning of the various steps?”). 4. Performance Indicator Parameters of a PSA Process So far, it has been shown that PSA processes have a tremendous flexibility in design (so large that sometimes is misleading). A completely different number of columns can be used and also a quite large number of cycles are possible. In order to provide a certain “common framework” to understand some aspects of PSA engineering, it is desirable to have some “performance indicators” (PI) which will be the ones that will define how well performs the PSA Table 1: Performance indicator parameters for a PSA process. Less-adsorbed gas is the product More-adsorbed gas is the product CT Purity= i =yT i CiB B Purity=N =yi Ni = 1 C i T t T T i = 1 C i B tCBQBdt 0CiQidt CiF QiF tcycle CTQTdt 0 i i process. For the definition of such parameters, the PSA process depicted in Figure 2 can be considered. The image shows a PSA process with X columns (X can also be unity) accommodating a specific mass of adsorbent per column (wads) and with multiple connection lines to accommodate very different steps. The objective is to separate component i from N components and two cases may be found: either the purpose of the PSA is to purify the less adsorbed gas or alternatively, to concentrate the more adsorbed gas. The most common PI found in PSA processes are listed in Table 1 [134]. The two first PI (purity and recovery) are related to the separation efficiency of the PSA and normally establish the GO/NO GO condition in process design. If such specifications are satisfied, the “fingerprint” of the unit is evaluated by the productivity. Finally, the energetic considerations should be made. Since the process is so flexible, it is difficult to define an energetic PI other than saying that is the sum of all work used for compression and vacuum. Note that the recovery and productivity have an integral term that is mainly due to variations in flowrate in the exit streams. Recovery = Productivity = Recovery= 0 Productivity = tcycle CBQBdt 0 i i i i CiF QiF Xwadstcycle Energy = sum of all compression and vacuum sources used XwadstcyclePDF Image | Advances in Pressure Swing Adsorption for Gas Separation

PDF Search Title:

Advances in Pressure Swing Adsorption for Gas SeparationOriginal File Name Searched:

982934.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |