PDF Publication Title:

Text from PDF Page: 017

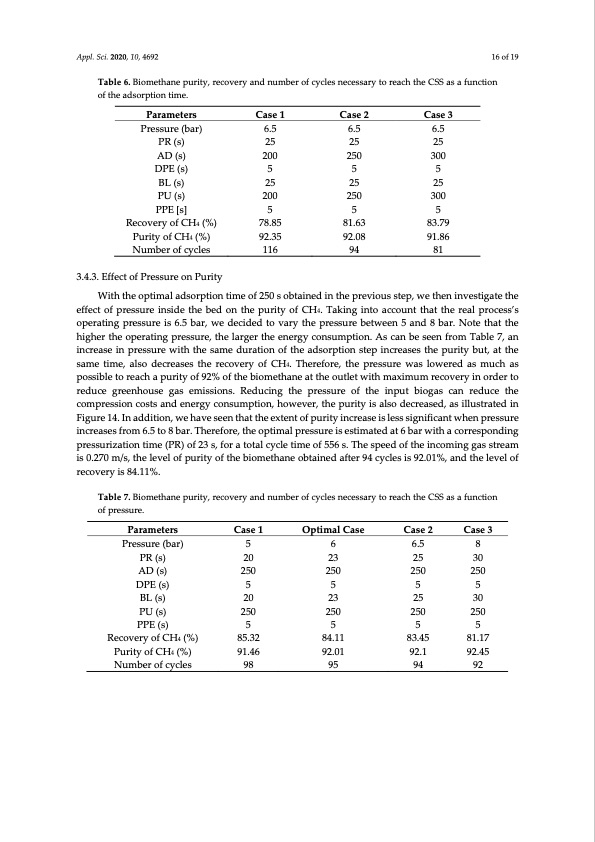

Appl. Sci. 2020, 10, 4692 16 of 19 Table 6. Biomethane purity, recovery and number of cycles necessary to reach the CSS as a function of the adsorption time. Parameters Pressure (bar) PR (s) AD (s) Case 1 6.5 25 200 Case 2 6.5 25 250 Case 3 6.5 25 300 Recovery of CH4 (%) Purity of CH4 (%) Number of cycles 3.4.3. Effect of Pressure on Purity 78.85 92.35 116 81.63 92.08 94 83.79 91.86 81 DPE(s) 5 5 5 BL (s) 25 25 25 PU (s) 200 250 300 PPE[s] 5 5 5 With the optimal adsorption time of 250 s obtained in the previous step, we then investigate the effect of pressure inside the bed on the purity of CH4. Taking into account that the real process’s operating pressure is 6.5 bar, we decided to vary the pressure between 5 and 8 bar. Note that the higher the operating pressure, the larger the energy consumption. As can be seen from Table 7, an increase in pressure with the same duration of the adsorption step increases the purity but, at the same time, also decreases the recovery of CH4. Therefore, the pressure was lowered as much as possible to reach a purity of 92% of the biomethane at the outlet with maximum recovery in order to reduce greenhouse gas emissions. Reducing the pressure of the input biogas can reduce the compression costs and energy consumption, however, the purity is also decreased, as illustrated in Figure 14. In addition, we have seen that the extent of purity increase is less significant when pressure increases from 6.5 to 8 bar. Therefore, the optimal pressure is estimated at 6 bar with a corresponding pressurization time (PR) of 23 s, for a total cycle time of 556 s. The speed of the incoming gas stream is 0.270 m/s, the level of purity of the biomethane obtained after 94 cycles is 92.01%, and the level of recovery is 84.11%. Table 7. Biomethane purity, recovery and number of cycles necessary to reach the CSS as a function of pressure. Parameters Pressure (bar) PR (s) AD (s) Case 1 5 20 250 Optimal Case 6 23 250 Case 2 6.5 25 250 Case 3 8 30 250 DPE(s) 5 5 55 BL (s) 20 23 25 30 PU (s) 250 250 250 250 PPE(s) 5 5 55 Recovery of CH4 (%) Purity of CH4 (%) Number of cycles 85.32 91.46 98 84.11 92.01 95 83.45 81.17 92.1 92.45 94 92PDF Image | Biogas Six-Step Pressure Swing Adsorption

PDF Search Title:

Biogas Six-Step Pressure Swing AdsorptionOriginal File Name Searched:

applsci-10-04692.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |