PDF Publication Title:

Text from PDF Page: 007

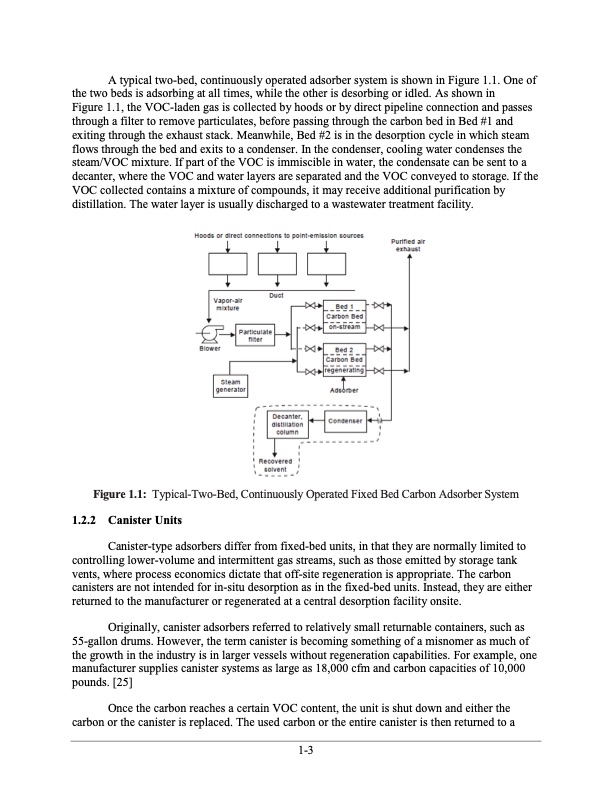

A typical two-bed, continuously operated adsorber system is shown in Figure 1.1. One of the two beds is adsorbing at all times, while the other is desorbing or idled. As shown in Figure 1.1, the VOC-laden gas is collected by hoods or by direct pipeline connection and passes through a filter to remove particulates, before passing through the carbon bed in Bed #1 and exiting through the exhaust stack. Meanwhile, Bed #2 is in the desorption cycle in which steam flows through the bed and exits to a condenser. In the condenser, cooling water condenses the steam/VOC mixture. If part of the VOC is immiscible in water, the condensate can be sent to a decanter, where the VOC and water layers are separated and the VOC conveyed to storage. If the VOC collected contains a mixture of compounds, it may receive additional purification by distillation. The water layer is usually discharged to a wastewater treatment facility. Figure 1.1: Typical-Two-Bed, Continuously Operated Fixed Bed Carbon Adsorber System 1.2.2 Canister Units Canister-type adsorbers differ from fixed-bed units, in that they are normally limited to controlling lower-volume and intermittent gas streams, such as those emitted by storage tank vents, where process economics dictate that off-site regeneration is appropriate. The carbon canisters are not intended for in-situ desorption as in the fixed-bed units. Instead, they are either returned to the manufacturer or regenerated at a central desorption facility onsite. Originally, canister adsorbers referred to relatively small returnable containers, such as 55-gallon drums. However, the term canister is becoming something of a misnomer as much of the growth in the industry is in larger vessels without regeneration capabilities. For example, one manufacturer supplies canister systems as large as 18,000 cfm and carbon capacities of 10,000 pounds. [25] Once the carbon reaches a certain VOC content, the unit is shut down and either the carbon or the canister is replaced. The used carbon or the entire canister is then returned to a 1-3PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |