PDF Publication Title:

Text from PDF Page: 036

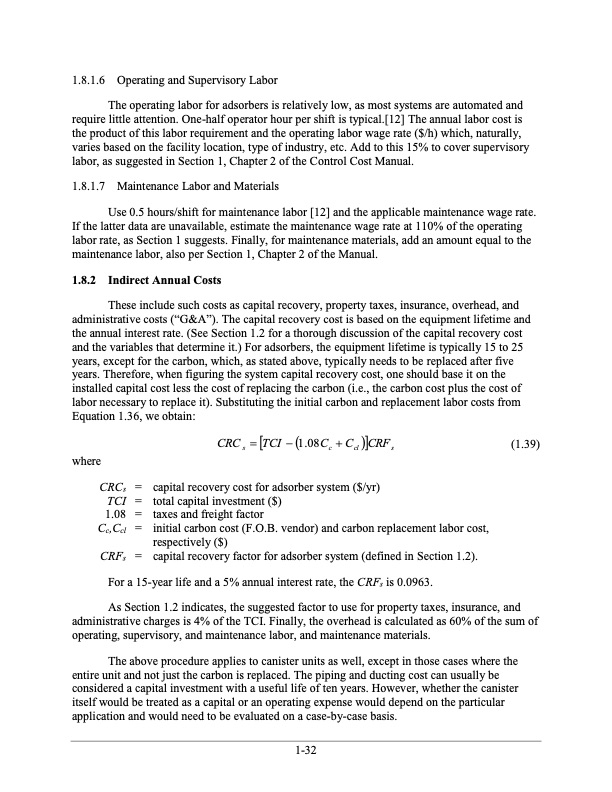

1.8.1.6 Operating and Supervisory Labor The operating labor for adsorbers is relatively low, as most systems are automated and require little attention. One-half operator hour per shift is typical.[12] The annual labor cost is the product of this labor requirement and the operating labor wage rate ($/h) which, naturally, varies based on the facility location, type of industry, etc. Add to this 15% to cover supervisory labor, as suggested in Section 1, Chapter 2 of the Control Cost Manual. 1.8.1.7 Maintenance Labor and Materials Use 0.5 hours/shift for maintenance labor [12] and the applicable maintenance wage rate. If the latter data are unavailable, estimate the maintenance wage rate at 110% of the operating labor rate, as Section 1 suggests. Finally, for maintenance materials, add an amount equal to the maintenance labor, also per Section 1, Chapter 2 of the Manual. 1.8.2 Indirect Annual Costs These include such costs as capital recovery, property taxes, insurance, overhead, and administrative costs (“G&A”). The capital recovery cost is based on the equipment lifetime and the annual interest rate. (See Section 1.2 for a thorough discussion of the capital recovery cost and the variables that determine it.) For adsorbers, the equipment lifetime is typically 15 to 25 years, except for the carbon, which, as stated above, typically needs to be replaced after five years. Therefore, when figuring the system capital recovery cost, one should base it on the installed capital cost less the cost of replacing the carbon (i.e., the carbon cost plus the cost of labor necessary to replace it). Substituting the initial carbon and replacement labor costs from Equation 1.36, where CRCs = TCI = 1.08 = Cc,Ccl = CRFs = we obtain: CRCs TCI 1.08Cc Ccl CRFs (1.39) capital recovery cost for adsorber system ($/yr) total capital investment ($) taxes and freight factor initial carbon cost (F.O.B. vendor) and carbon replacement labor cost, respectively ($) capital recovery factor for adsorber system (defined in Section 1.2). For a 15-year life and a 5% annual interest rate, the CRFs is 0.0963. As Section 1.2 indicates, the suggested factor to use for property taxes, insurance, and administrative charges is 4% of the TCI. Finally, the overhead is calculated as 60% of the sum of operating, supervisory, and maintenance labor, and maintenance materials. The above procedure applies to canister units as well, except in those cases where the entire unit and not just the carbon is replaced. The piping and ducting cost can usually be considered a capital investment with a useful life of ten years. However, whether the canister itself would be treated as a capital or an operating expense would depend on the particular application and would need to be evaluated on a case-by-case basis. 1-32PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |