PDF Publication Title:

Text from PDF Page: 042

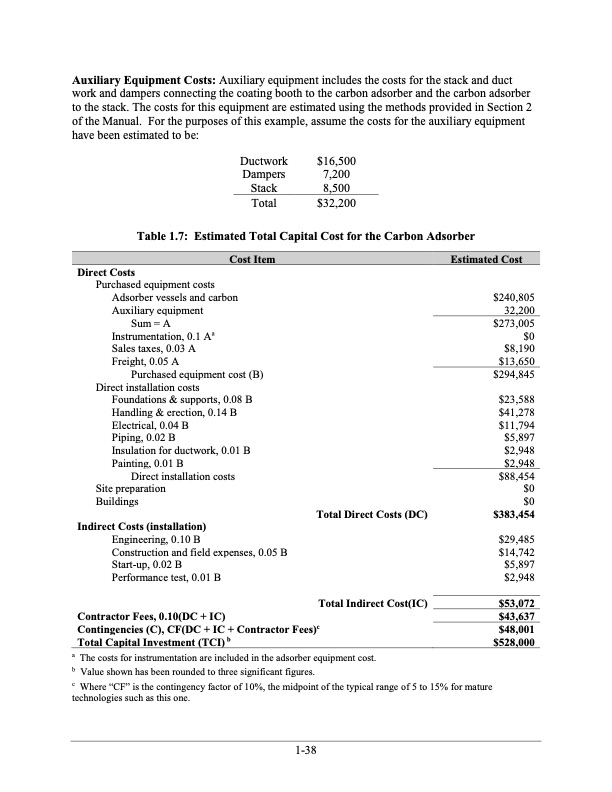

Auxiliary Equipment Costs: Auxiliary equipment includes the costs for the stack and duct work and dampers connecting the coating booth to the carbon adsorber and the carbon adsorber to the stack. The costs for this equipment are estimated using the methods provided in Section 2 of the Manual. For the purposes of this example, assume the costs for the auxiliary equipment have been estimated to be: Ductwork Dampers Stack Total $16,500 7,200 8,500 $32,200 Table 1.7: Estimated Total Capital Cost for the Carbon Adsorber Cost Item Estimated Cost $240,805 32,200 $273,005 $0 $8,190 $13,650 $294,845 $23,588 $41,278 $11,794 $5,897 $2,948 $2,948 $88,454 $0 $0 $383,454 $29,485 $14,742 $5,897 $2,948 $53,072 $43,637 $48,001 $528,000 Direct Costs Purchased equipment costs Adsorber vessels and carbon Auxiliary equipment Sum = A Instrumentation, 0.1 Aa Sales taxes, 0.03 A Freight, 0.05 A Purchased equipment cost (B) Direct installation costs Foundations & supports, 0.08 B Handling & erection, 0.14 B Electrical, 0.04 B Piping, 0.02 B Insulation for ductwork, 0.01 B Painting, 0.01 B Direct installation costs Site preparation Buildings Indirect Costs (installation) Engineering, 0.10 B Construction and field expenses, 0.05 B Start-up, 0.02 B Performance test, 0.01 B Total Direct Costs (DC) Total Indirect Cost(IC) Contractor Fees, 0.10(DC + IC) Contingencies (C), CF(DC + IC + Contractor Fees)c Total Capital Investment (TCI) b a b c technologies such as this one. The costs for instrumentation are included in the adsorber equipment cost. Value shown has been rounded to three significant figures. Where “CF” is the contingency factor of 10%, the midpoint of the typical range of 5 to 15% for mature 1-38PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |