PDF Publication Title:

Text from PDF Page: 046

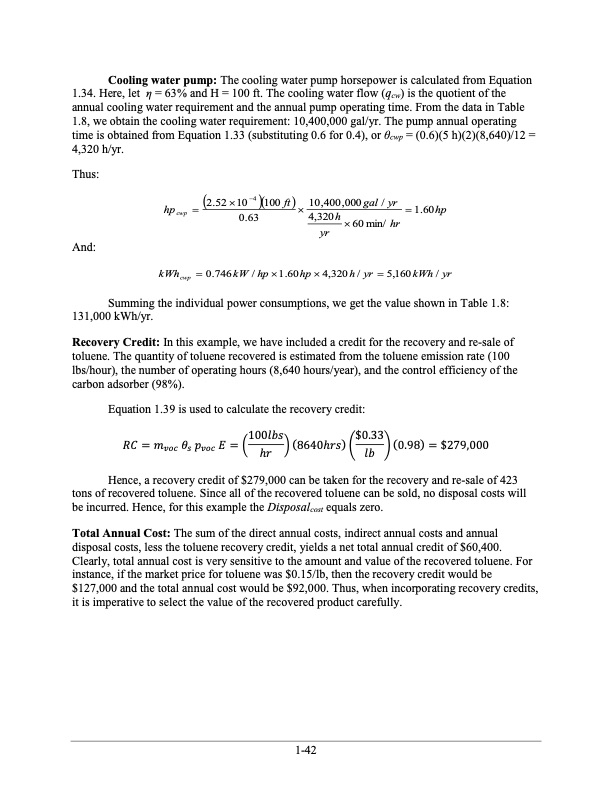

Cooling water pump: The cooling water pump horsepower is calculated from Equation 1.34. Here, let η = 63% and H = 100 ft. The cooling water flow (qcw) is the quotient of the annual cooling water requirement and the annual pump operating time. From the data in Table 1.8, we obtain the cooling water requirement: 10,400,000 gal/yr. The pump annual operating time is obtained from Equation 1.33 (substituting 0.6 for 0.4), or θcwp = (0.6)(5 h)(2)(8,640)/12 = 4,320 h/yr. Thus: And: 131,000 kWh/yr. Recovery Credit: In this example, we have included a credit for the recovery and re-sale of toluene. The quantity of toluene recovered is estimated from the toluene emission rate (100 lbs/hour), the number of operating hours (8,640 hours/year), and the control efficiency of the carbon adsorber (98%). Equation 1.39 is used to calculate the recovery credit: 𝑅𝐶 = 𝑚𝑣𝑜𝑐 𝜃𝑠 𝑝𝑣𝑜𝑐 𝐸 = (100𝑙𝑏𝑠) (8640h𝑟𝑠) ($0.33) (0.98) = $279,000 h𝑟 𝑙𝑏 Hence, a recovery credit of $279,000 can be taken for the recovery and re-sale of 423 tons of recovered toluene. Since all of the recovered toluene can be sold, no disposal costs will be incurred. Hence, for this example the Disposalcost equals zero. Total Annual Cost: The sum of the direct annual costs, indirect annual costs and annual disposal costs, less the toluene recovery credit, yields a net total annual credit of $60,400. Clearly, total annual cost is very sensitive to the amount and value of the recovered toluene. For instance, if the market price for toluene was $0.15/lb, then the recovery credit would be $127,000 and the total annual cost would be $92,000. Thus, when incorporating recovery credits, it is imperative to select the value of the recovered product carefully. hpcwp 2.52104 100 ft 10,400,000gal / yr 1.60hp 0.63 4,320h60min/ hr yr kWhcwp 0.746kW/hp1.60hp4,320h/yr5,160kWh/yr Summing the individual power consumptions, we get the value shown in Table 1.8: 1-42PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |