PDF Publication Title:

Text from PDF Page: 002

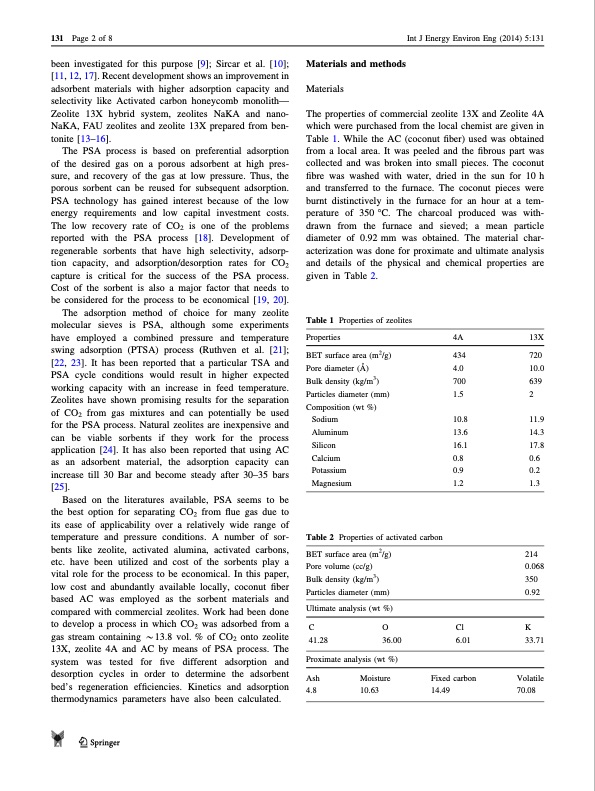

131 Page 2 of 8 Int J Energy Environ Eng (2014) 5:131 been investigated for this purpose [9]; Sircar et al. [10]; [11, 12, 17]. Recent development shows an improvement in adsorbent materials with higher adsorption capacity and selectivity like Activated carbon honeycomb monolith— Zeolite 13X hybrid system, zeolites NaKA and nano- NaKA, FAU zeolites and zeolite 13X prepared from ben- tonite [13–16]. The PSA process is based on preferential adsorption of the desired gas on a porous adsorbent at high pres- sure, and recovery of the gas at low pressure. Thus, the porous sorbent can be reused for subsequent adsorption. PSA technology has gained interest because of the low energy requirements and low capital investment costs. The low recovery rate of CO2 is one of the problems reported with the PSA process [18]. Development of regenerable sorbents that have high selectivity, adsorp- tion capacity, and adsorption/desorption rates for CO2 capture is critical for the success of the PSA process. Cost of the sorbent is also a major factor that needs to be considered for the process to be economical [19, 20]. The adsorption method of choice for many zeolite molecular sieves is PSA, although some experiments have employed a combined pressure and temperature swing adsorption (PTSA) process (Ruthven et al. [21]; [22, 23]. It has been reported that a particular TSA and PSA cycle conditions would result in higher expected working capacity with an increase in feed temperature. Zeolites have shown promising results for the separation of CO2 from gas mixtures and can potentially be used for the PSA process. Natural zeolites are inexpensive and can be viable sorbents if they work for the process application [24]. It has also been reported that using AC as an adsorbent material, the adsorption capacity can increase till 30 Bar and become steady after 30–35 bars [25]. Based on the literatures available, PSA seems to be the best option for separating CO2 from flue gas due to its ease of applicability over a relatively wide range of temperature and pressure conditions. A number of sor- bents like zeolite, activated alumina, activated carbons, etc. have been utilized and cost of the sorbents play a vital role for the process to be economical. In this paper, low cost and abundantly available locally, coconut fiber based AC was employed as the sorbent materials and compared with commercial zeolites. Work had been done to develop a process in which CO2 was adsorbed from a gas stream containing *13.8 vol. % of CO2 onto zeolite 13X, zeolite 4A and AC by means of PSA process. The system was tested for five different adsorption and desorption cycles in order to determine the adsorbent bed’s regeneration efficiencies. Kinetics and adsorption thermodynamics parameters have also been calculated. Materials and methods Materials The properties of commercial zeolite 13X and Zeolite 4A which were purchased from the local chemist are given in Table 1. While the AC (coconut fiber) used was obtained from a local area. It was peeled and the fibrous part was collected and was broken into small pieces. The coconut fibre was washed with water, dried in the sun for 10 h and transferred to the furnace. The coconut pieces were burnt distinctively in the furnace for an hour at a tem- perature of 350 °C. The charcoal produced was with- drawn from the furnace and sieved; a mean particle diameter of 0.92 mm was obtained. The material char- acterization was done for proximate and ultimate analysis and details of the physical and chemical properties are given in Table 2. Table 1 Properties of zeolites Properties BET surface area (m2/g) Pore diameter (A ̊ ) Bulk density (kg/m3) Particles diameter (mm) Composition (wt %) Sodium Aluminum Silicon Calcium Potassium Magnesium Table 2 Properties of activated carbon 4A 13X 434 720 4.0 10.0 700 639 1.5 2 10.8 11.9 13.6 14.3 16.1 17.8 0.8 0.6 0.9 0.2 1.2 1.3 214 0.068 350 0.92 Cl K 6.01 33.71 carbon Volatile 70.08 BET surface area (m2/g) Pore volume (cc/g) Bulk density (kg/m3) Particles diameter (mm) Ultimate analysis (wt %) CO 41.28 36.00 Proximate analysis (wt %) Ash Moisture 4.8 10.63 Fixed 14.49 123PDF Image | Carbon dioxide adsorption on zeolites and activated carbon PSA

PDF Search Title:

Carbon dioxide adsorption on zeolites and activated carbon PSAOriginal File Name Searched:

Carbon_dioxide_adsorption_on_zeolites_and_activate.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |