PDF Publication Title:

Text from PDF Page: 005

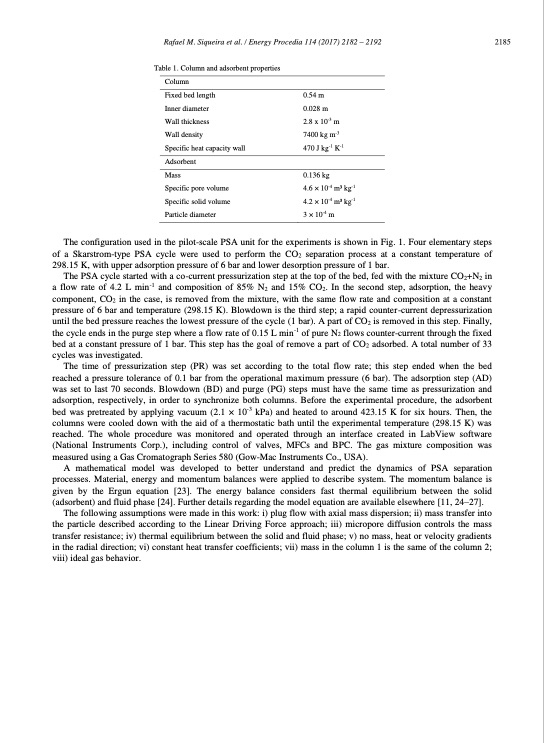

Rafael M. Siqueira et al. / Energy Procedia 114 (2017) 2182 – 2192 2185 Table 1. Column and adsorbent properties Column Fixed bed length Inner diameter Wall thickness Wall density Specific heat capacity wall Adsorbent Mass Specific pore volume Specific solid volume Particle diameter 0.54 m 0.028 m 2.8 x 10-3 m 7400 kg m-3 470 J kg-1 K-1 0.136 kg 4.6 × 10-4 m3 kg-1 4.2 × 10-4 m3 kg-1 3 × 10-4 m The configuration used in the pilot-scale PSA unit for the experiments is shown in Fig. 1. Four elementary steps of a Skarstrom-type PSA cycle were used to perform the CO2 separation process at a constant temperature of 298.15 K, with upper adsorption pressure of 6 bar and lower desorption pressure of 1 bar. The PSA cycle started with a co-current pressurization step at the top of the bed, fed with the mixture CO2+N2 in a flow rate of 4.2 L min-1 and composition of 85% N2 and 15% CO2. In the second step, adsorption, the heavy component, CO2 in the case, is removed from the mixture, with the same flow rate and composition at a constant pressure of 6 bar and temperature (298.15 K). Blowdown is the third step; a rapid counter-current depressurization until the bed pressure reaches the lowest pressure of the cycle (1 bar). A part of CO2 is removed in this step. Finally, the cycle ends in the purge step where a flow rate of 0.15 L min-1 of pure N2 flows counter-current through the fixed bed at a constant pressure of 1 bar. This step has the goal of remove a part of CO2 adsorbed. A total number of 33 cycles was investigated. The time of pressurization step (PR) was set according to the total flow rate; this step ended when the bed reached a pressure tolerance of 0.1 bar from the operational maximum pressure (6 bar). The adsorption step (AD) was set to last 70 seconds. Blowdown (BD) and purge (PG) steps must have the same time as pressurization and adsorption, respectively, in order to synchronize both columns. Before the experimental procedure, the adsorbent bed was pretreated by applying vacuum (2.1 × 10-3 kPa) and heated to around 423.15 K for six hours. Then, the columns were cooled down with the aid of a thermostatic bath until the experimental temperature (298.15 K) was reached. The whole procedure was monitored and operated through an interface created in LabView software (National Instruments Corp.), including control of valves, MFCs and BPC. The gas mixture composition was measured using a Gas Cromatograph Series 580 (Gow-Mac Instruments Co., USA). A mathematical model was developed to better understand and predict the dynamics of PSA separation processes. Material, energy and momentum balances were applied to describe system. The momentum balance is given by the Ergun equation [23]. The energy balance considers fast thermal equilibrium between the solid (adsorbent) and fluid phase [24]. Further details regarding the model equation are available elsewhere [11, 24–27]. The following assumptions were made in this work: i) plug flow with axial mass dispersion; ii) mass transfer into the particle described according to the Linear Driving Force approach; iii) micropore diffusion controls the mass transfer resistance; iv) thermal equilibrium between the solid and fluid phase; v) no mass, heat or velocity gradients in the radial direction; vi) constant heat transfer coefficients; vii) mass in the column 1 is the same of the column 2; viii) ideal gas behavior.PDF Image | Carbon Dioxide Capture by Pressure Swing Adsorption

PDF Search Title:

Carbon Dioxide Capture by Pressure Swing AdsorptionOriginal File Name Searched:

Carbondioxidecapturebypressureswingadsorption.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |