PDF Publication Title:

Text from PDF Page: 010

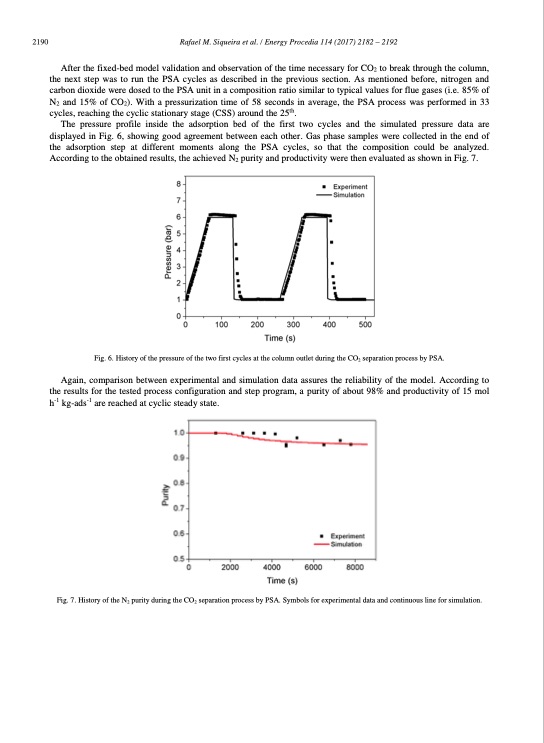

2190 Rafael M. Siqueira et al. / Energy Procedia 114 (2017) 2182 – 2192 After the fixed-bed model validation and observation of the time necessary for CO2 to break through the column, the next step was to run the PSA cycles as described in the previous section. As mentioned before, nitrogen and carbon dioxide were dosed to the PSA unit in a composition ratio similar to typical values for flue gases (i.e. 85% of N2 and 15% of CO2). With a pressurization time of 58 seconds in average, the PSA process was performed in 33 cycles, reaching the cyclic stationary stage (CSS) around the 25th. The pressure profile inside the adsorption bed of the first two cycles and the simulated pressure data are displayed in Fig. 6, showing good agreement between each other. Gas phase samples were collected in the end of the adsorption step at different moments along the PSA cycles, so that the composition could be analyzed. According to the obtained results, the achieved N2 purity and productivity were then evaluated as shown in Fig. 7. Fig. 6. History of the pressure of the two first cycles at the column outlet during the CO2 separation process by PSA. Again, comparison between experimental and simulation data assures the reliability of the model. According to the results for the tested process configuration and step program, a purity of about 98% and productivity of 15 mol h-1 kg-ads-1 are reached at cyclic steady state. Fig. 7. History of the N2 purity during the CO2 separation process by PSA. Symbols for experimental data and continuous line for simulation.PDF Image | Carbon Dioxide Capture by Pressure Swing Adsorption

PDF Search Title:

Carbon Dioxide Capture by Pressure Swing AdsorptionOriginal File Name Searched:

Carbondioxidecapturebypressureswingadsorption.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |