PDF Publication Title:

Text from PDF Page: 011

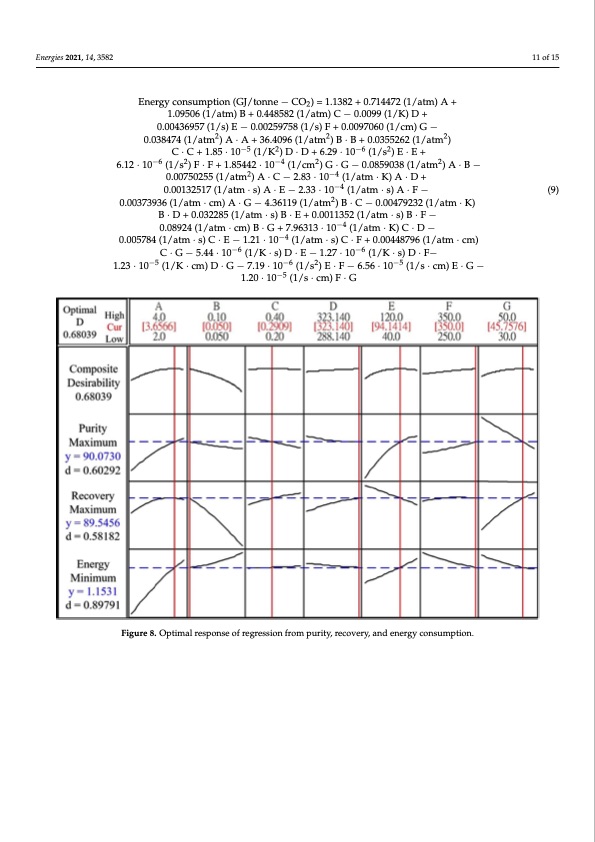

Energies 2021, 14, 3582 11 of 15 Energy consumption (GJ/tonne − CO2) = 1.1382 + 0.714472 (1/atm) A + 1.09506 (1/atm) B + 0.448582 (1/atm) C − 0.0099 (1/K) D + 0.00436957 (1/s) E − 0.00259758 (1/s) F + 0.0097060 (1/cm) G − 0.038474 (1/atm2) A · A + 36.4096 (1/atm2) B · B + 0.0355262 (1/atm2) C·C+1.85·10−5 (1/K2)D·D+6.29·10−6 (1/s2)E·E+ 6.12·10−6 (1/s2)F·F+1.85442·10−4 (1/cm2)G·G−0.0859038(1/atm2)A·B− 0.00750255(1/atm2)A·C−2.83·10−4 (1/atm·K)A·D+ 0.00132517(1/atm·s)A·E−2.33·10−4 (1/atm·s)A·F− 0.00373936 (1/atm · cm) A · G − 4.36119 (1/atm2) B · C − 0.00479232 (1/atm · K) B · D + 0.032285 (1/atm · s) B · E + 0.0011352 (1/atm · s) B · F − 0.08924(1/atm·cm)B·G+7.96313·10−4 (1/atm·K)C·D− 0.005784(1/atm·s)C·E−1.21·10−4 (1/atm·s)C·F+0.00448796(1/atm·cm) C·G−5.44·10−6 (1/K·s)D·E−1.27·10−6 (1/K·s)D·F− (9) 12 of 15 Energies 2021, 14, x FOR PEER R−EV5 IEW −6 2 −5 1.23·10 (1/K·cm)D·G−7.19·10 (1/s )E·F−6.56·10 1.20·10−5 (1/s·cm)F·G (1/s·cm)E·G− Figure8..Opttiimallresponseofregressionfrompurity, recovery,,andenerrgycconssumpttiion.. Table 9. Optimal operating conditions for capturing CO2 from flue gas using the three-bed nine-step PSA process. Parameters Feed composition Feed flow rate (m3/s, NTP) Bed length (m) Bed inner diameter (m) Bed volume (L) Bed porosity (-) Fluid viscosity (kg/m·s) Overall heat transfer coefficient (J/K· m2 ·s) Feed temperature (K) Surrounding temperature (K) Feed pressure (atm) Vacuum pressure (atm) Values 13.5 vol% CO2 and 86.5 vol% N2 1.21 × 10−3 0.46 0.16 9.25 0.6937 1.87 × 10−5 10.8 303.14 323.14 3.66 0.05PDF Image | CO2 captured from flue gas using the PSA process

PDF Search Title:

CO2 captured from flue gas using the PSA processOriginal File Name Searched:

energies-14-03582-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |