PDF Publication Title:

Text from PDF Page: 070

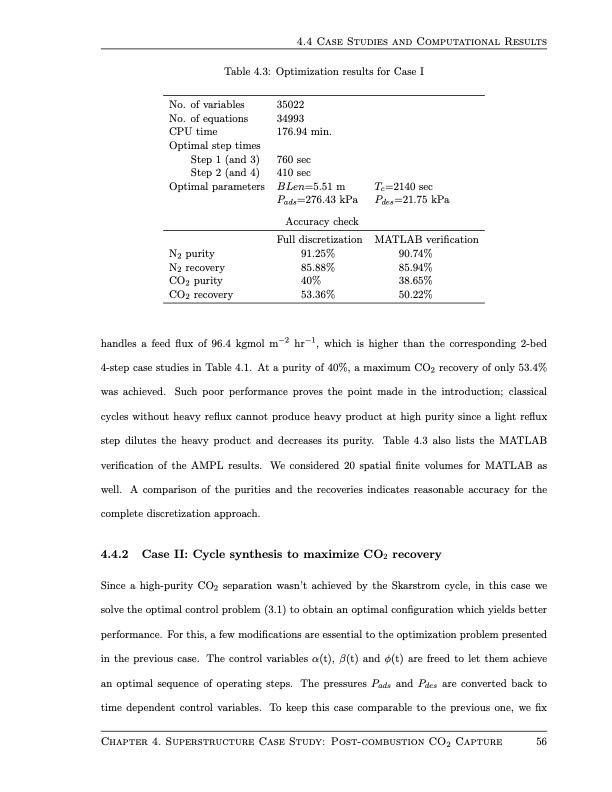

4.4 Case Studies and Computational Results Table 4.3: Optimization results for Case I No. of variables No. of equations CPU time Optimal step times Step 1 (and 3) Step 2 (and 4) Optimal parameters N2 purity N2 recovery CO2 purity CO2 recovery 35022 34993 176.94 min. 760 sec 410 sec BLen=5.51 m Pads=276.43 kPa Accuracy check Full discretization 91.25% 85.88% 40% 53.36% Tc=2140 sec Pdes=21.75 kPa MATLAB verification 90.74% 85.94% 38.65% 50.22% handles a feed flux of 96.4 kgmol m−2 hr−1, which is higher than the corresponding 2-bed 4-step case studies in Table 4.1. At a purity of 40%, a maximum CO2 recovery of only 53.4% was achieved. Such poor performance proves the point made in the introduction; classical cycles without heavy reflux cannot produce heavy product at high purity since a light reflux step dilutes the heavy product and decreases its purity. Table 4.3 also lists the MATLAB verification of the AMPL results. We considered 20 spatial finite volumes for MATLAB as well. A comparison of the purities and the recoveries indicates reasonable accuracy for the complete discretization approach. 4.4.2 Case II: Cycle synthesis to maximize CO2 recovery Since a high-purity CO2 separation wasn’t achieved by the Skarstrom cycle, in this case we solve the optimal control problem (3.1) to obtain an optimal configuration which yields better performance. For this, a few modifications are essential to the optimization problem presented in the previous case. The control variables α(t), β(t) and φ(t) are freed to let them achieve an optimal sequence of operating steps. The pressures Pads and Pdes are converted back to time dependent control variables. To keep this case comparable to the previous one, we fix Chapter 4. Superstructure Case Study: Post-combustion CO2 Capture 56PDF Image | Design and Operation of Pressure Swing Adsorption Processes

PDF Search Title:

Design and Operation of Pressure Swing Adsorption ProcessesOriginal File Name Searched:

anshul_thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |