PDF Publication Title:

Text from PDF Page: 081

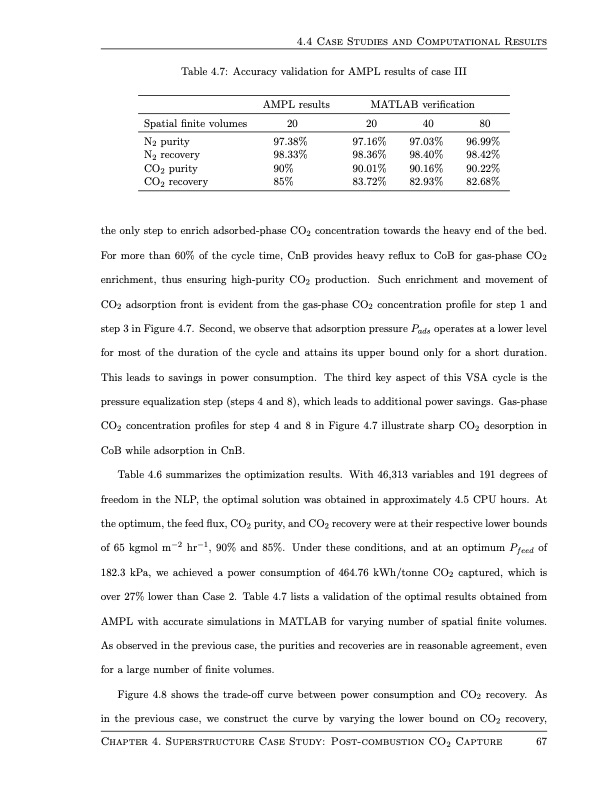

4.4 Case Studies and Computational Results Table 4.7: Accuracy validation for AMPL results of case III Spatial finite volumes N2 purity N2 recovery CO2 purity CO2 recovery AMPL results 20 97.38% 98.33% 90% 85% MATLAB verification 20 40 97.16% 97.03% 98.36% 98.40% 90.01% 90.16% 83.72% 82.93% 80 96.99% 98.42% 90.22% 82.68% the only step to enrich adsorbed-phase CO2 concentration towards the heavy end of the bed. For more than 60% of the cycle time, CnB provides heavy reflux to CoB for gas-phase CO2 enrichment, thus ensuring high-purity CO2 production. Such enrichment and movement of CO2 adsorption front is evident from the gas-phase CO2 concentration profile for step 1 and step 3 in Figure 4.7. Second, we observe that adsorption pressure Pads operates at a lower level for most of the duration of the cycle and attains its upper bound only for a short duration. This leads to savings in power consumption. The third key aspect of this VSA cycle is the pressure equalization step (steps 4 and 8), which leads to additional power savings. Gas-phase CO2 concentration profiles for step 4 and 8 in Figure 4.7 illustrate sharp CO2 desorption in CoB while adsorption in CnB. Table 4.6 summarizes the optimization results. With 46,313 variables and 191 degrees of freedom in the NLP, the optimal solution was obtained in approximately 4.5 CPU hours. At the optimum, the feed flux, CO2 purity, and CO2 recovery were at their respective lower bounds of 65 kgmol m−2 hr−1, 90% and 85%. Under these conditions, and at an optimum Pfeed of 182.3 kPa, we achieved a power consumption of 464.76 kWh/tonne CO2 captured, which is over 27% lower than Case 2. Table 4.7 lists a validation of the optimal results obtained from AMPL with accurate simulations in MATLAB for varying number of spatial finite volumes. As observed in the previous case, the purities and recoveries are in reasonable agreement, even for a large number of finite volumes. Figure 4.8 shows the trade-off curve between power consumption and CO2 recovery. As in the previous case, we construct the curve by varying the lower bound on CO2 recovery, Chapter 4. Superstructure Case Study: Post-combustion CO2 Capture 67PDF Image | Design and Operation of Pressure Swing Adsorption Processes

PDF Search Title:

Design and Operation of Pressure Swing Adsorption ProcessesOriginal File Name Searched:

anshul_thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |