PDF Publication Title:

Text from PDF Page: 098

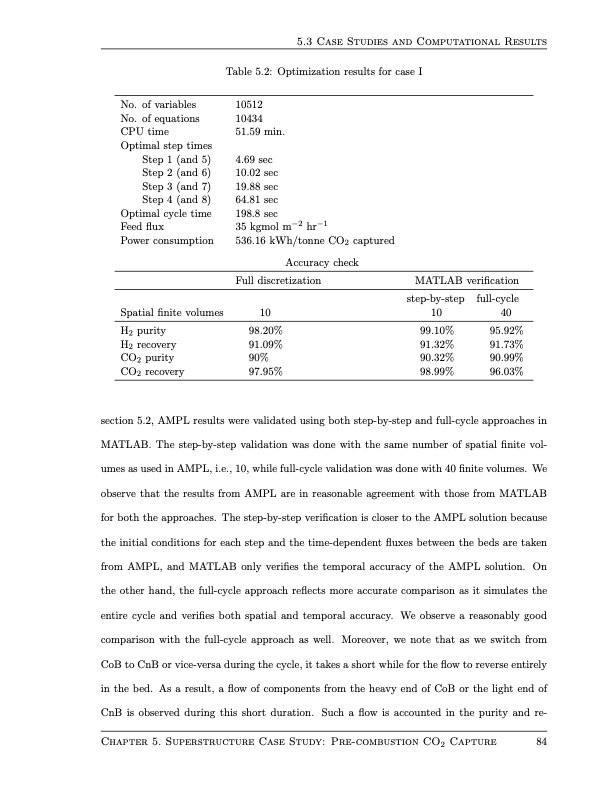

5.3 Case Studies and Computational Results Table 5.2: Optimization results for case I No. of variables No. of equations CPU time Optimal step times Step 1 (and 5) Step 2 (and 6) Step 3 (and 7) Step 4 (and 8) Optimal cycle time Feed flux Power consumption Spatial finite volumes H2 purity H2 recovery CO2 purity CO2 recovery 10512 10434 51.59 min. 4.69 sec 10.02 sec 19.88 sec 64.81 sec 198.8 sec 35 kgmol m−2 hr−1 536.16 kWh/tonne CO2 captured Accuracy check Full discretization 10 98.20% 91.09% 90% 97.95% MATLAB verification step-by-step full-cycle 10 40 99.10% 95.92% 91.32% 91.73% 90.32% 90.99% 98.99% 96.03% section 5.2, AMPL results were validated using both step-by-step and full-cycle approaches in MATLAB. The step-by-step validation was done with the same number of spatial finite vol- umes as used in AMPL, i.e., 10, while full-cycle validation was done with 40 finite volumes. We observe that the results from AMPL are in reasonable agreement with those from MATLAB for both the approaches. The step-by-step verification is closer to the AMPL solution because the initial conditions for each step and the time-dependent fluxes between the beds are taken from AMPL, and MATLAB only verifies the temporal accuracy of the AMPL solution. On the other hand, the full-cycle approach reflects more accurate comparison as it simulates the entire cycle and verifies both spatial and temporal accuracy. We observe a reasonably good comparison with the full-cycle approach as well. Moreover, we note that as we switch from CoB to CnB or vice-versa during the cycle, it takes a short while for the flow to reverse entirely in the bed. As a result, a flow of components from the heavy end of CoB or the light end of CnB is observed during this short duration. Such a flow is accounted in the purity and re- Chapter 5. Superstructure Case Study: Pre-combustion CO2 Capture 84PDF Image | Design and Operation of Pressure Swing Adsorption Processes

PDF Search Title:

Design and Operation of Pressure Swing Adsorption ProcessesOriginal File Name Searched:

anshul_thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |