PDF Publication Title:

Text from PDF Page: 100

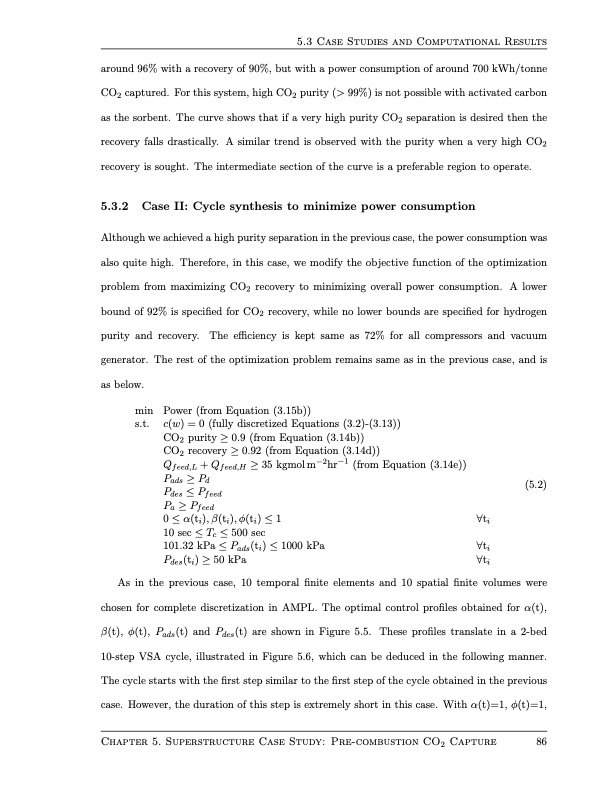

5.3 Case Studies and Computational Results around 96% with a recovery of 90%, but with a power consumption of around 700 kWh/tonne CO2 captured. For this system, high CO2 purity (> 99%) is not possible with activated carbon as the sorbent. The curve shows that if a very high purity CO2 separation is desired then the recovery falls drastically. A similar trend is observed with the purity when a very high CO2 recovery is sought. The intermediate section of the curve is a preferable region to operate. 5.3.2 Case II: Cycle synthesis to minimize power consumption Although we achieved a high purity separation in the previous case, the power consumption was also quite high. Therefore, in this case, we modify the objective function of the optimization problem from maximizing CO2 recovery to minimizing overall power consumption. A lower bound of 92% is specified for CO2 recovery, while no lower bounds are specified for hydrogen purity and recovery. The efficiency is kept same as 72% for all compressors and vacuum generator. The rest of the optimization problem remains same as in the previous case, and is as below. min Power (from Equation (3.15b)) s.t. c(w) = 0 (fully discretized Equations (3.2)-(3.13)) CO2 purity ≥ 0.9 (from Equation (3.14b)) CO2 recovery ≥ 0.92 (from Equation (3.14d)) Qfeed,L+Qfeed,H ≥35kgmolm−2hr−1 (fromEquation(3.14e)) Pads ≥ Pd Pdes ≤ Pfeed Pa ≥ Pfeed 0 ≤ α(ti), β(ti), φ(ti) ≤ 1 ∀ti 10sec≤Tc ≤500sec 101.32 kPa ≤ Pads(ti) ≤ 1000 kPa ∀ti Pdes(ti) ≥ 50 kPa ∀ti (5.2) As in the previous case, 10 temporal finite elements and 10 spatial finite volumes were chosen for complete discretization in AMPL. The optimal control profiles obtained for α(t), β(t), φ(t), Pads(t) and Pdes(t) are shown in Figure 5.5. These profiles translate in a 2-bed 10-step VSA cycle, illustrated in Figure 5.6, which can be deduced in the following manner. The cycle starts with the first step similar to the first step of the cycle obtained in the previous case. However, the duration of this step is extremely short in this case. With α(t)=1, φ(t)=1, Chapter 5. Superstructure Case Study: Pre-combustion CO2 Capture 86PDF Image | Design and Operation of Pressure Swing Adsorption Processes

PDF Search Title:

Design and Operation of Pressure Swing Adsorption ProcessesOriginal File Name Searched:

anshul_thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |