PDF Publication Title:

Text from PDF Page: 222

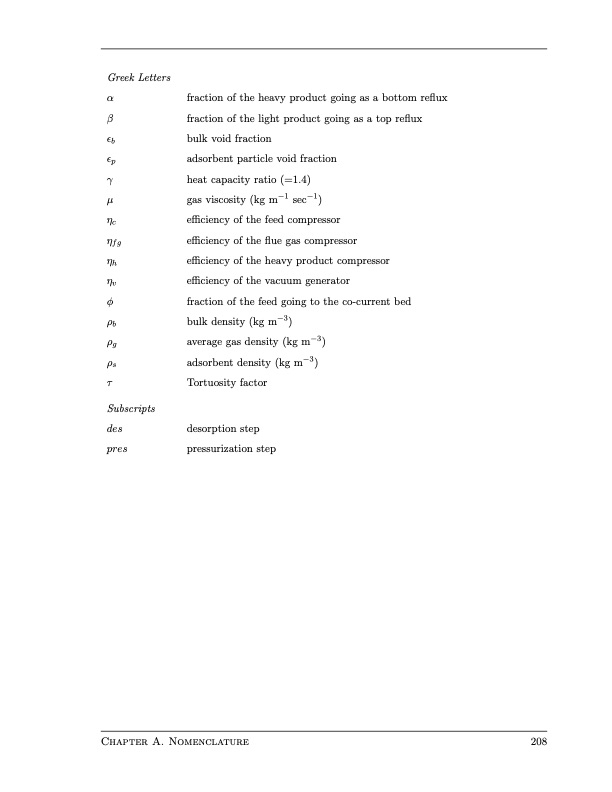

Greek Letters α fraction of the heavy product going as a bottom reflux β fraction of the light product going as a top reflux εb bulk void fraction εp adsorbent particle void fraction γ heat capacity ratio (=1.4) μ gas viscosity (kg m−1 sec−1 ) ηc efficiency of the feed compressor ηfg efficiency of the flue gas compressor ηh efficiency of the heavy product compressor ηv efficiency of the vacuum generator φ fraction of the feed going to the co-current bed ρb bulk density (kg m−3 ) ρg average gas density (kg m−3 ) ρs adsorbent density (kg m−3) τ Tortuosity factor Subscripts des desorption step pres pressurization step Chapter A. Nomenclature 208PDF Image | Design and Operation of Pressure Swing Adsorption Processes

PDF Search Title:

Design and Operation of Pressure Swing Adsorption ProcessesOriginal File Name Searched:

anshul_thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |