PDF Publication Title:

Text from PDF Page: 034

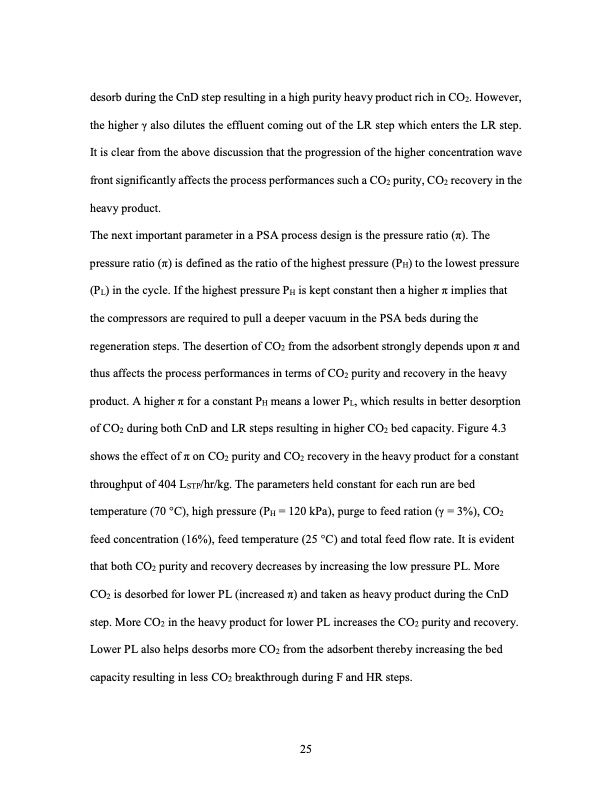

desorb during the CnD step resulting in a high purity heavy product rich in CO2. However, the higher γ also dilutes the effluent coming out of the LR step which enters the LR step. It is clear from the above discussion that the progression of the higher concentration wave front significantly affects the process performances such a CO2 purity, CO2 recovery in the heavy product. The next important parameter in a PSA process design is the pressure ratio (π). The pressure ratio (π) is defined as the ratio of the highest pressure (PH) to the lowest pressure (PL) in the cycle. If the highest pressure PH is kept constant then a higher π implies that the compressors are required to pull a deeper vacuum in the PSA beds during the regeneration steps. The desertion of CO2 from the adsorbent strongly depends upon π and thus affects the process performances in terms of CO2 purity and recovery in the heavy product. A higher π for a constant PH means a lower PL, which results in better desorption of CO2 during both CnD and LR steps resulting in higher CO2 bed capacity. Figure 4.3 shows the effect of π on CO2 purity and CO2 recovery in the heavy product for a constant throughput of 404 LSTP/hr/kg. The parameters held constant for each run are bed temperature (70 °C), high pressure (PH = 120 kPa), purge to feed ration (γ = 3%), CO2 feed concentration (16%), feed temperature (25 °C) and total feed flow rate. It is evident that both CO2 purity and recovery decreases by increasing the low pressure PL. More CO2 is desorbed for lower PL (increased π) and taken as heavy product during the CnD step. More CO2 in the heavy product for lower PL increases the CO2 purity and recovery. Lower PL also helps desorbs more CO2 from the adsorbent thereby increasing the bed capacity resulting in less CO2 breakthrough during F and HR steps. 25PDF Image | Development of a Pressure Swing Adsorption (PSA) Cycle for CO2 Capture

PDF Search Title:

Development of a Pressure Swing Adsorption (PSA) Cycle for CO2 CaptureOriginal File Name Searched:

PSA-co2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |