PDF Publication Title:

Text from PDF Page: 009

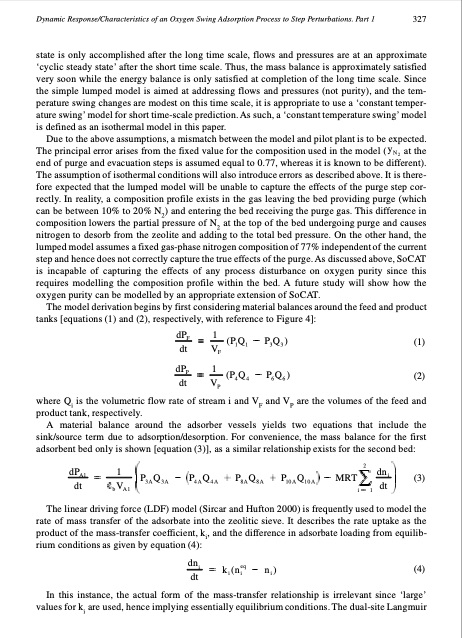

Dynamic Response/Characteristics of an Oxygen Swing Adsorption Process to Step Perturbations. Part 1 327 state is only accomplished after the long time scale, flows and pressures are at an approximate ‘cyclic steady state’ after the short time scale. Thus, the mass balance is approximately satisfied very soon while the energy balance is only satisfied at completion of the long time scale. Since the simple lumped model is aimed at addressing flows and pressures (not purity), and the tem- perature swing changes are modest on this time scale, it is appropriate to use a ‘constant temper- ature swing’ model for short time-scale prediction. As such, a ‘constant temperature swing’ model is defined as an isothermal model in this paper. Due to the above assumptions, a mismatch between the model and pilot plant is to be expected. The principal error arises from the fixed value for the composition used in the model (yN2 at the end of purge and evacuation steps is assumed equal to 0.77, whereas it is known to be different). The assumption of isothermal conditions will also introduce errors as described above. It is there- fore expected that the lumped model will be unable to capture the effects of the purge step cor- rectly. In reality, a composition profile exists in the gas leaving the bed providing purge (which can be between 10% to 20% N2) and entering the bed receiving the purge gas. This difference in composition lowers the partial pressure of N2 at the top of the bed undergoing purge and causes nitrogen to desorb from the zeolite and adding to the total bed pressure. On the other hand, the lumped model assumes a fixed gas-phase nitrogen composition of 77% independent of the current step and hence does not correctly capture the true effects of the purge. As discussed above, SoCAT is incapable of capturing the effects of any process disturbance on oxygen purity since this requires modelling the composition profile within the bed. A future study will show how the oxygen purity can be modelled by an appropriate extension of SoCAT. The model derivation begins by first considering material balances around the feed and product tanks [equations (1) and (2), respectively, with reference to Figure 4]: (1) (2) where Qi is the volumetric flow rate of stream i and VF and VP are the volumes of the feed and product tank, respectively. A material balance around the adsorber vessels yields two equations that include the sink/source term due to adsorption/desorption. For convenience, the mass balance for the first adsorbent bed only is shown [equation (3)], as a similar relationship exists for the second bed: dPA1 1 2 dni dt V P3AQ3A P4AQ4A P8AQ8A P10AQ10A MRT dt (3) b A1 i 1 The linear driving force (LDF) model (Sircar and Hufton 2000) is frequently used to model the rate of mass transfer of the adsorbate into the zeolitic sieve. It describes the rate uptake as the product of the mass-transfer coefficient, ki, and the difference in adsorbate loading from equilib- rium conditions as given by equation (4): (4) In this instance, the actual form of the mass-transfer relationship is irrelevant since ‘large’ values for ki are used, hence implying essentially equilibrium conditions. The dual-site Langmuir dPF 1 (P1Q1 P3Q3) dt VF dPP 1 (P4Q4 P6Q6) dt VP dni k (neq n ) dtii iPDF Image | Dynamic Response and Characteristics of an Oxygen Vacuum Swing Adsorption

PDF Search Title:

Dynamic Response and Characteristics of an Oxygen Vacuum Swing AdsorptionOriginal File Name Searched:

026361703322405051.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |