PDF Publication Title:

Text from PDF Page: 016

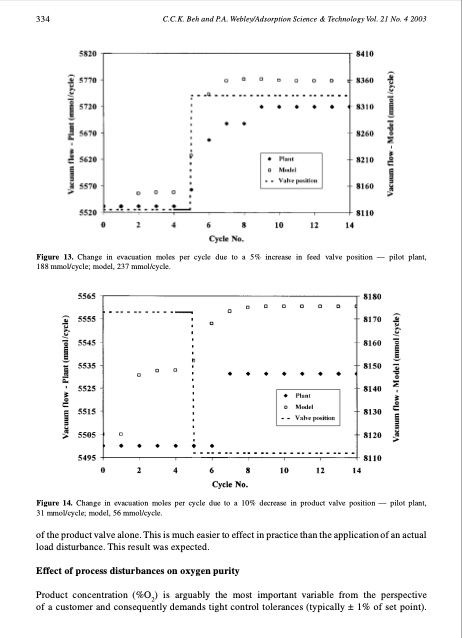

334 C.C.K. Beh and P.A. Webley/Adsorption Science & Technology Vol. 21 No. 4 2003 Figure 13. Change in evacuation moles per cycle due to a 5% increase in feed valve position — pilot plant, 188 mmol/cycle; model, 237 mmol/cycle. Figure 14. Change in evacuation moles per cycle due to a 10% decrease in product valve position — pilot plant, 31 mmol/cycle; model, 56 mmol/cycle. of the product valve alone. This is much easier to effect in practice than the application of an actual load disturbance. This result was expected. Effect of process disturbances on oxygen purity Product concentration (%O2) is arguably the most important variable from the perspective of a customer and consequently demands tight control tolerances (typically ± 1% of set point).PDF Image | Dynamic Response and Characteristics of an Oxygen Vacuum Swing Adsorption

PDF Search Title:

Dynamic Response and Characteristics of an Oxygen Vacuum Swing AdsorptionOriginal File Name Searched:

026361703322405051.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |