PDF Publication Title:

Text from PDF Page: 019

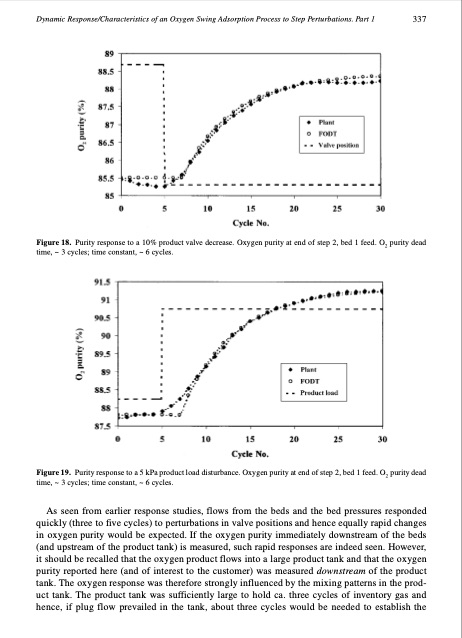

Dynamic Response/Characteristics of an Oxygen Swing Adsorption Process to Step Perturbations. Part 1 337 Figure 18. Purity response to a 10% product valve decrease. Oxygen purity at end of step 2, bed 1 feed. O2 purity dead time, ~ 3 cycles; time constant, ~ 6 cycles. Figure 19. Purity response to a 5 kPa product load disturbance. Oxygen purity at end of step 2, bed 1 feed. O2 purity dead time, ~ 3 cycles; time constant, ~ 6 cycles. As seen from earlier response studies, flows from the beds and the bed pressures responded quickly (three to five cycles) to perturbations in valve positions and hence equally rapid changes in oxygen purity would be expected. If the oxygen purity immediately downstream of the beds (and upstream of the product tank) is measured, such rapid responses are indeed seen. However, it should be recalled that the oxygen product flows into a large product tank and that the oxygen purity reported here (and of interest to the customer) was measured downstream of the product tank. The oxygen response was therefore strongly influenced by the mixing patterns in the prod- uct tank. The product tank was sufficiently large to hold ca. three cycles of inventory gas and hence, if plug flow prevailed in the tank, about three cycles would be needed to establish thePDF Image | Dynamic Response and Characteristics of an Oxygen Vacuum Swing Adsorption

PDF Search Title:

Dynamic Response and Characteristics of an Oxygen Vacuum Swing AdsorptionOriginal File Name Searched:

026361703322405051.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |