PDF Publication Title:

Text from PDF Page: 107

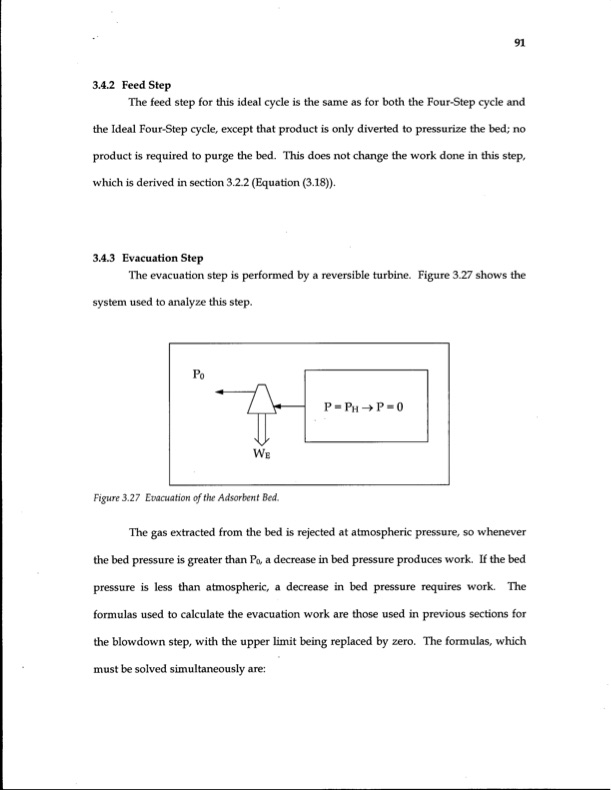

3.4.2 Feed Step The feed step for this ideal cycle is the same as for both the Four-Step cycleand the Ideal Four-Step cycle, except that product is only diverted to pressurize the bed; no product is required to purge the bed. This does not change the work done in this step, which is derived in section 3.2.2 (Equation (3.18)). 3.4.3 Evacuation Step The evacuation step is performed by a reversible turbine. Figure 3.27 shows the system used to analyze this step. Po —A. P = P H -> P = 0 W E Figure 3.27 Evacuation ofthe Adsorbent Bed. /r \ / The gas extracted from the bed is rejected at atmospheric pressure, so whenever the bed pressure is greater than Po, a decrease in bed pressure produces work. If the bed pressure is less than atmospheric, a decrease in bed pressure requires work. The formulas used to calculate the evacuation work are those used in previous sections for the blowdown step, with the upper limit being replaced by zero. The formulas, which must be solved simultaneously are: 91PDF Image | Energy Efficiency of Gas Separation Pressure Swing Adsorption

PDF Search Title:

Energy Efficiency of Gas Separation Pressure Swing AdsorptionOriginal File Name Searched:

ubc_1997-0009.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |