PDF Publication Title:

Text from PDF Page: 004

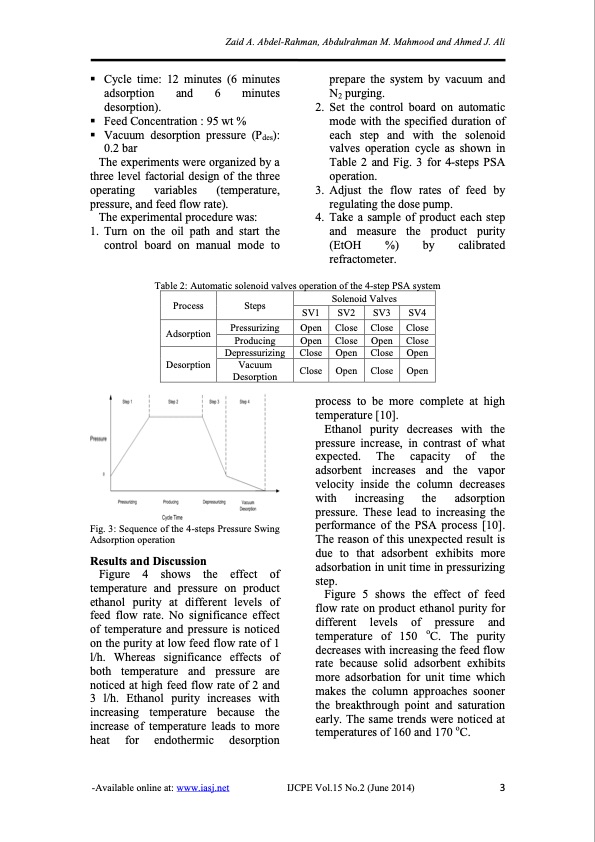

Cycle time: 12 minutes (6 minutes adsorption and 6 minutes desorption). Feed Concentration : 95 wt % Vacuum desorption pressure (Pdes): 0.2 bar The experiments were organized by a three level factorial design of the three operating variables (temperature, pressure, and feed flow rate). The experimental procedure was: 1. Turn on the oil path and start the control board on manual mode to prepare the system by vacuum and N2 purging. 2. Set the control board on automatic mode with the specified duration of each step and with the solenoid valves operation cycle as shown in Table 2 and Fig. 3 for 4-steps PSA operation. 3. Adjust the flow rates of feed by regulating the dose pump. 4. Take a sample of product each step and measure the product purity (EtOH %) by calibrated refractometer. Zaid A. Abdel-Rahman, Abdulrahman M. Mahmood and Ahmed J. Ali Table 2: Automatic solenoid valves operation of the 4-step PSA system Process Adsorption Desorption Steps Solenoid Valves SV1 SV2 SV3 SV4 Open Close Close Close Open Close Open Close Close Open Close Open Close Open Close Open process to be more complete at high temperature [10]. Ethanol purity decreases with the pressure increase, in contrast of what expected. The capacity of the adsorbent increases and the vapor velocity inside the column decreases with increasing the adsorption pressure. These lead to increasing the performance of the PSA process [10]. The reason of this unexpected result is due to that adsorbent exhibits more adsorbation in unit time in pressurizing step. Figure 5 shows the effect of feed flow rate on product ethanol purity for different levels of o pressure and temperature of 150 C. The purity decreases with increasing the feed flow rate because solid adsorbent exhibits more adsorbation for unit time which makes the column approaches sooner the breakthrough point and saturation early. The same trends were noticed at temperatures of 160 and 170 oC. Pressurizing Producing Depressurizing Vacuum Desorption Fig. 3: Sequence of the 4-steps Pressure Swing Adsorption operation Results and Discussion Figure 4 shows the effect of temperature and pressure on product ethanol purity at different levels of feed flow rate. No significance effect of temperature and pressure is noticed on the purity at low feed flow rate of 1 l/h. Whereas significance effects of both temperature and pressure are noticed at high feed flow rate of 2 and 3 l/h. Ethanol purity increases with increasing temperature because the increase of temperature leads to more heat for endothermic desorption -Available online at: www.iasj.net IJCPE Vol.15 No.2 (June 2014) 3PDF Image | Ethanol-Water Separation by Pressure Swing Adsorption

PDF Search Title:

Ethanol-Water Separation by Pressure Swing AdsorptionOriginal File Name Searched:

Ethanol-Water-Separation-PSA.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |