PDF Publication Title:

Text from PDF Page: 006

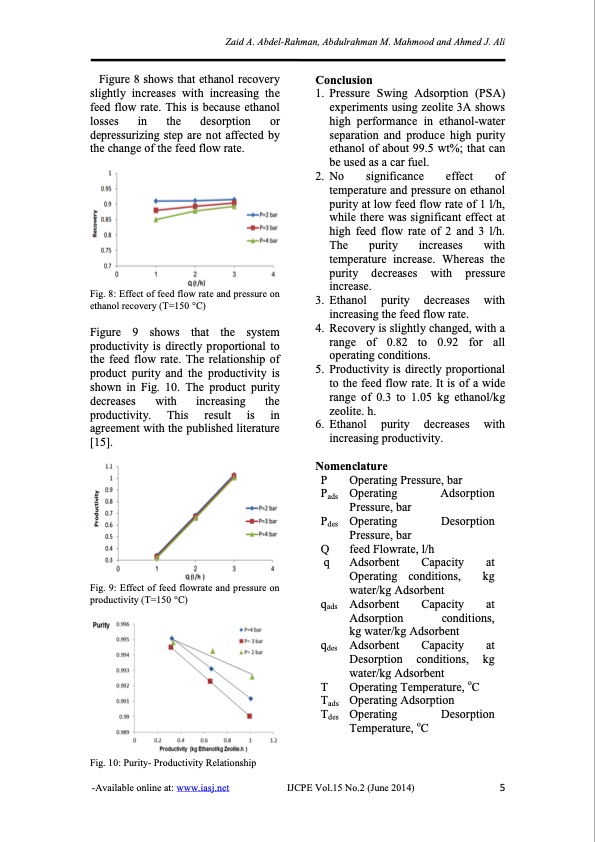

Figure 8 shows that ethanol recovery slightly increases with increasing the feed flow rate. This is because ethanol losses in the desorption or depressurizing step are not affected by the change of the feed flow rate. Conclusion 1. Pressure Swing Adsorption (PSA) experiments using zeolite 3A shows high performance in ethanol-water separation and produce high purity ethanol of about 99.5 wt%; that can be used as a car fuel. 2. No significance effect of temperature and pressure on ethanol purity at low feed flow rate of 1 l/h, while there was significant effect at high feed flow rate of 2 and 3 l/h. The purity increases with temperature increase. Whereas the purity decreases with pressure increase. 3. Ethanol purity decreases with increasing the feed flow rate. 4. Recovery is slightly changed, with a range of 0.82 to 0.92 for all operating conditions. 5. Productivity is directly proportional to the feed flow rate. It is of a wide range of 0.3 to 1.05 kg ethanol/kg zeolite. h. 6. Ethanol purity decreases with increasing productivity. Nomenclature P Operating Pressure, bar Pads Operating Adsorption Pressure, bar Pdes Operating Desorption Pressure, bar Q feed Flowrate, l/h q Adsorbent Capacity at Operating conditions, kg water/kg Adsorbent qads Adsorbent Capacity at Adsorption conditions, kg water/kg Adsorbent qdes Adsorbent Capacity at Desorption conditions, kg water/kg Adsorbent T Operating Temperature, oC Tads Operating Adsorption Tdes Operating o Desorption Temperature, C Zaid A. Abdel-Rahman, Abdulrahman M. Mahmood and Ahmed J. Ali Fig. 8: Effect of feed flow rate and pressure on ethanol recovery (T=150 °C) Figure 9 shows that the system productivity is directly proportional to the feed flow rate. The relationship of product purity and the productivity is shown in Fig. 10. The product purity decreases with increasing the productivity. This result is in agreement with the published literature [15]. Fig. 9: Effect of feed flowrate and pressure on productivity (T=150 °C) Fig. 10: Purity- Productivity Relationship -Available online at: www.iasj.net IJCPE Vol.15 No.2 (June 2014) 5PDF Image | Ethanol-Water Separation by Pressure Swing Adsorption

PDF Search Title:

Ethanol-Water Separation by Pressure Swing AdsorptionOriginal File Name Searched:

Ethanol-Water-Separation-PSA.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |