PDF Publication Title:

Text from PDF Page: 006

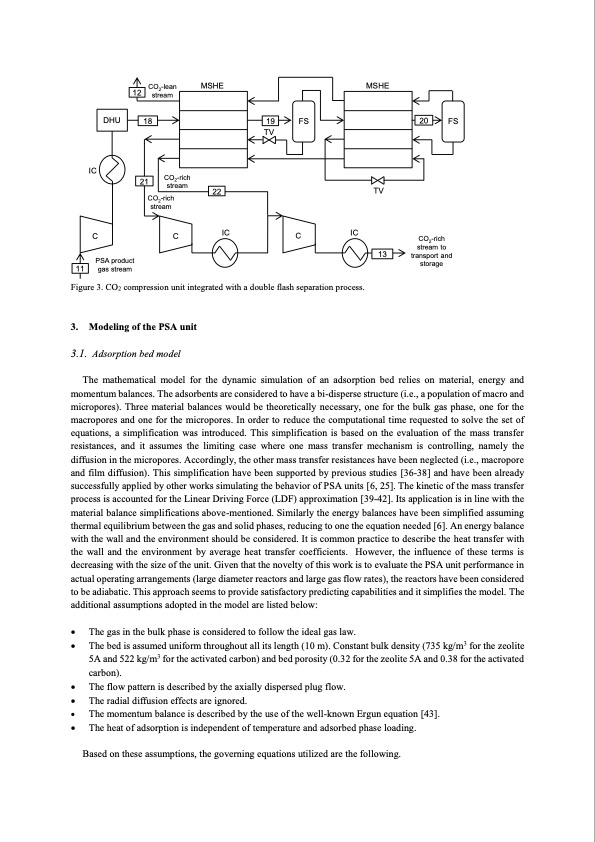

12 CO2-lean MSHE stream MSHE TV 13 DHU 18 IC 21 19 FS TV 20 FS CO2-rich stream to transport and storage CO2-rich stream 22 CO2-rich stream 11 C C IC C IC PSA product gas stream Figure 3. CO2 compression unit integrated with a double flash separation process. 3. Modeling of the PSA unit 3.1. Adsorption bed model The mathematical model for the dynamic simulation of an adsorption bed relies on material, energy and momentum balances. The adsorbents are considered to have a bi-disperse structure (i.e., a population of macro and micropores). Three material balances would be theoretically necessary, one for the bulk gas phase, one for the macropores and one for the micropores. In order to reduce the computational time requested to solve the set of equations, a simplification was introduced. This simplification is based on the evaluation of the mass transfer resistances, and it assumes the limiting case where one mass transfer mechanism is controlling, namely the diffusion in the micropores. Accordingly, the other mass transfer resistances have been neglected (i.e., macropore and film diffusion). This simplification have been supported by previous studies [36-38] and have been already successfully applied by other works simulating the behavior of PSA units [6, 25]. The kinetic of the mass transfer process is accounted for the Linear Driving Force (LDF) approximation [39-42]. Its application is in line with the material balance simplifications above-mentioned. Similarly the energy balances have been simplified assuming thermal equilibrium between the gas and solid phases, reducing to one the equation needed [6]. An energy balance with the wall and the environment should be considered. It is common practice to describe the heat transfer with the wall and the environment by average heat transfer coefficients. However, the influence of these terms is decreasing with the size of the unit. Given that the novelty of this work is to evaluate the PSA unit performance in actual operating arrangements (large diameter reactors and large gas flow rates), the reactors have been considered to be adiabatic. This approach seems to provide satisfactory predicting capabilities and it simplifies the model. The additional assumptions adopted in the model are listed below: The gas in the bulk phase is considered to follow the ideal gas law. The bed is assumed uniform throughout all its length (10 m). Constant bulk density (735 kg/m3 for the zeolite 5A and 522 kg/m3 for the activated carbon) and bed porosity (0.32 for the zeolite 5A and 0.38 for the activated carbon). The flow pattern is described by the axially dispersed plug flow. The radial diffusion effects are ignored. The momentum balance is described by the use of the well-known Ergun equation [43]. The heat of adsorption is independent of temperature and adsorbed phase loading. Based on these assumptions, the governing equations utilized are the following.PDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |