PDF Publication Title:

Text from PDF Page: 008

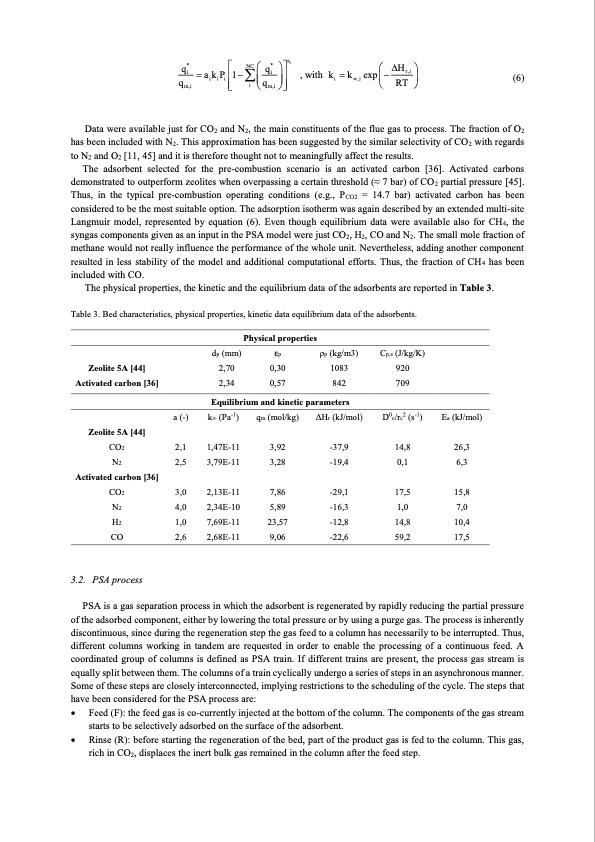

q* NCq*ai H qiiiq RT i a k P 1 i , with k k exp r,i i ,i (6) m,i im,i Data were available just for CO2 and N2, the main constituents of the flue gas to process. The fraction of O2 has been included with N2. This approximation has been suggested by the similar selectivity of CO2 with regards to N2 and O2 [11, 45] and it is therefore thought not to meaningfully affect the results. The adsorbent selected for the pre-combustion scenario is an activated carbon [36]. Activated carbons demonstrated to outperform zeolites when overpassing a certain threshold (≈ 7 bar) of CO2 partial pressure [45]. Thus, in the typical pre-combustion operating conditions (e.g., PCO2 = 14.7 bar) activated carbon has been considered to be the most suitable option. The adsorption isotherm was again described by an extended multi-site Langmuir model, represented by equation (6). Even though equilibrium data were available also for CH4, the syngas components given as an input in the PSA model were just CO2, H2, CO and N2. The small mole fraction of methane would not really influence the performance of the whole unit. Nevertheless, adding another component resulted in less stability of the model and additional computational efforts. Thus, the fraction of CH4 has been included with CO. The physical properties, the kinetic and the equilibrium data of the adsorbents are reported in Table 3. Table 3. Bed characteristics, physical properties, kinetic data equilibrium data of the adsorbents. Zeolite 5A [44] Activated carbon [36] Zeolite 5A [44] CO2 N2 Activated carbon [36] CO2 N2 H2 CO 3.2. PSA process Physical properties dp (mm) εp 2,70 0,30 2,34 0,57 ρp (kg/m3) 1083 842 Cp,s (J/kg/K) 920 709 D0c/rc2 (s-1) 14,8 0,1 17,5 1,0 14,8 59,2 Equilibrium and kinetic parameters a (-) 2,1 2,5 3,0 4,0 1,0 2,6 k∞ (Pa-1) 1,47E-11 3,79E-11 2,13E-11 2,34E-10 7,69E-11 2,68E-11 qm (mol/kg) 3,92 3,28 7,86 5,89 23,57 9,06 ΔHr (kJ/mol) -37,9 -19,4 -29,1 -16,3 -12,8 -22,6 Ea (kJ/mol) 26,3 6,3 15,8 7,0 10,4 17,5 PSA is a gas separation process in which the adsorbent is regenerated by rapidly reducing the partial pressure of the adsorbed component, either by lowering the total pressure or by using a purge gas. The process is inherently discontinuous, since during the regeneration step the gas feed to a column has necessarily to be interrupted. Thus, different columns working in tandem are requested in order to enable the processing of a continuous feed. A coordinated group of columns is defined as PSA train. If different trains are present, the process gas stream is equally split between them. The columns of a train cyclically undergo a series of steps in an asynchronous manner. Some of these steps are closely interconnected, implying restrictions to the scheduling of the cycle. The steps that have been considered for the PSA process are: Feed (F): the feed gas is co-currently injected at the bottom of the column. The components of the gas stream starts to be selectively adsorbed on the surface of the adsorbent. Rinse (R): before starting the regeneration of the bed, part of the product gas is fed to the column. This gas, rich in CO2, displaces the inert bulk gas remained in the column after the feed step.PDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |