PDF Publication Title:

Text from PDF Page: 020

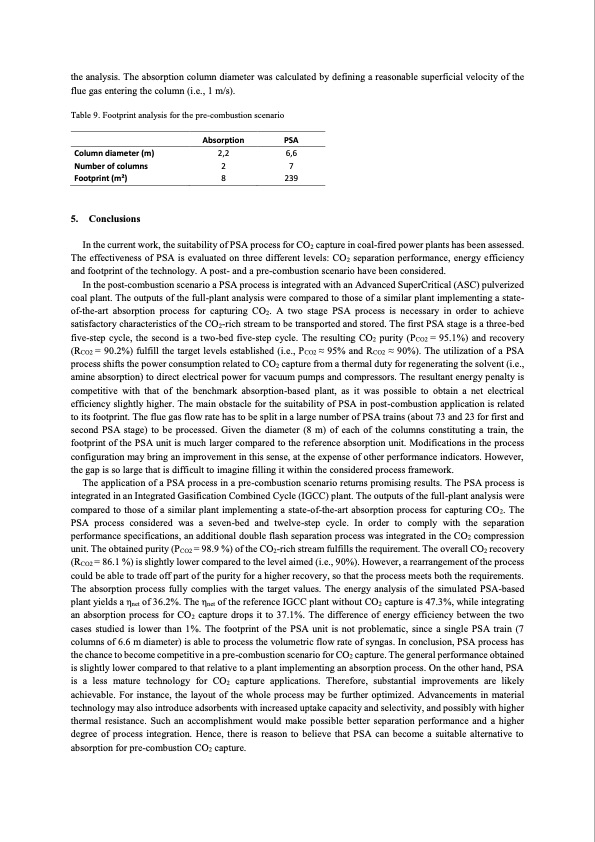

the analysis. The absorption column diameter was calculated by defining a reasonable superficial velocity of the flue gas entering the column (i.e., 1 m/s). Table 9. Footprint analysis for the pre-combustion scenario Column diameter (m) Number of columns Footprint (m2) 5. Conclusions Absorption PSA 2,2 6,6 2 7 8 239 In the current work, the suitability of PSA process for CO2 capture in coal-fired power plants has been assessed. The effectiveness of PSA is evaluated on three different levels: CO2 separation performance, energy efficiency and footprint of the technology. A post- and a pre-combustion scenario have been considered. In the post-combustion scenario a PSA process is integrated with an Advanced SuperCritical (ASC) pulverized coal plant. The outputs of the full-plant analysis were compared to those of a similar plant implementing a state- of-the-art absorption process for capturing CO2. A two stage PSA process is necessary in order to achieve satisfactory characteristics of the CO2-rich stream to be transported and stored. The first PSA stage is a three-bed five-step cycle, the second is a two-bed five-step cycle. The resulting CO2 purity (PCO2 = 95.1%) and recovery (RCO2 = 90.2%) fulfill the target levels established (i.e., PCO2 ≈ 95% and RCO2 ≈ 90%). The utilization of a PSA process shifts the power consumption related to CO2 capture from a thermal duty for regenerating the solvent (i.e., amine absorption) to direct electrical power for vacuum pumps and compressors. The resultant energy penalty is competitive with that of the benchmark absorption-based plant, as it was possible to obtain a net electrical efficiency slightly higher. The main obstacle for the suitability of PSA in post-combustion application is related to its footprint. The flue gas flow rate has to be split in a large number of PSA trains (about 73 and 23 for first and second PSA stage) to be processed. Given the diameter (8 m) of each of the columns constituting a train, the footprint of the PSA unit is much larger compared to the reference absorption unit. Modifications in the process configuration may bring an improvement in this sense, at the expense of other performance indicators. However, the gap is so large that is difficult to imagine filling it within the considered process framework. The application of a PSA process in a pre-combustion scenario returns promising results. The PSA process is integrated in an Integrated Gasification Combined Cycle (IGCC) plant. The outputs of the full-plant analysis were compared to those of a similar plant implementing a state-of-the-art absorption process for capturing CO2. The PSA process considered was a seven-bed and twelve-step cycle. In order to comply with the separation performance specifications, an additional double flash separation process was integrated in the CO2 compression unit. The obtained purity (PCO2 = 98.9 %) of the CO2-rich stream fulfills the requirement. The overall CO2 recovery (RCO2 = 86.1 %) is slightly lower compared to the level aimed (i.e., 90%). However, a rearrangement of the process could be able to trade off part of the purity for a higher recovery, so that the process meets both the requirements. The absorption process fully complies with the target values. The energy analysis of the simulated PSA-based plant yields a ηnet of 36.2%. The ηnet of the reference IGCC plant without CO2 capture is 47.3%, while integrating an absorption process for CO2 capture drops it to 37.1%. The difference of energy efficiency between the two cases studied is lower than 1%. The footprint of the PSA unit is not problematic, since a single PSA train (7 columns of 6.6 m diameter) is able to process the volumetric flow rate of syngas. In conclusion, PSA process has the chance to become competitive in a pre-combustion scenario for CO2 capture. The general performance obtained is slightly lower compared to that relative to a plant implementing an absorption process. On the other hand, PSA is a less mature technology for CO2 capture applications. Therefore, substantial improvements are likely achievable. For instance, the layout of the whole process may be further optimized. Advancements in material technology may also introduce adsorbents with increased uptake capacity and selectivity, and possibly with higher thermal resistance. Such an accomplishment would make possible better separation performance and a higher degree of process integration. Hence, there is reason to believe that PSA can become a suitable alternative to absorption for pre-combustion CO2 capture.PDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |