PDF Publication Title:

Text from PDF Page: 026

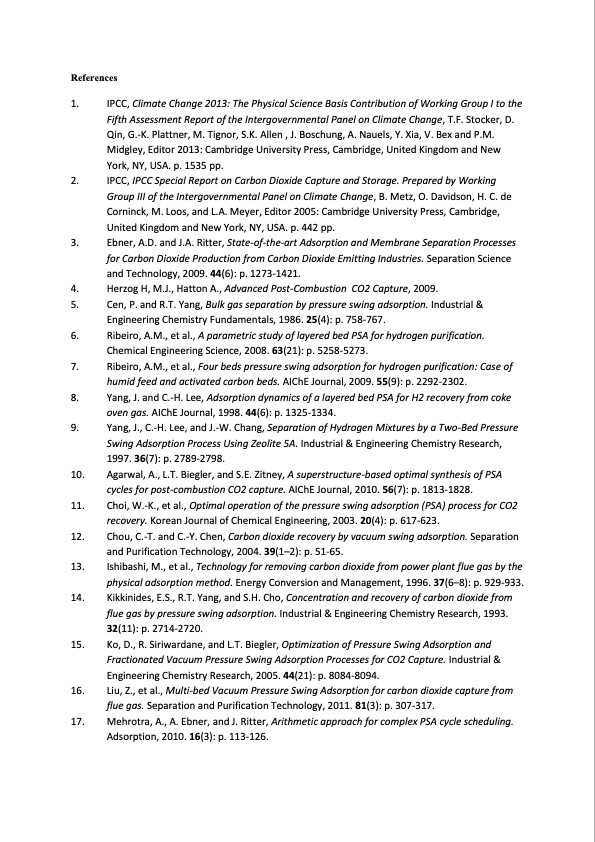

References 1. IPCC, Climate Change 2013: The Physical Science Basis Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, T.F. Stocker, D. Qin, G.-K. Plattner, M. Tignor, S.K. Allen , J. Boschung, A. Nauels, Y. Xia, V. Bex and P.M. Midgley, Editor 2013: Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA. p. 1535 pp. 2. IPCC, IPCC Special Report on Carbon Dioxide Capture and Storage. Prepared by Working Group III of the Intergovernmental Panel on Climate Change, B. Metz, O. Davidson, H. C. de Corninck, M. Loos, and L.A. Meyer, Editor 2005: Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA. p. 442 pp. 3. Ebner, A.D. and J.A. Ritter, State-of-the-art Adsorption and Membrane Separation Processes for Carbon Dioxide Production from Carbon Dioxide Emitting Industries. Separation Science and Technology, 2009. 44(6): p. 1273-1421. 4. Herzog H, M.J., Hatton A., Advanced Post-Combustion CO2 Capture, 2009. 5. Cen, P. and R.T. Yang, Bulk gas separation by pressure swing adsorption. Industrial & Engineering Chemistry Fundamentals, 1986. 25(4): p. 758-767. 6. Ribeiro, A.M., et al., A parametric study of layered bed PSA for hydrogen purification. Chemical Engineering Science, 2008. 63(21): p. 5258-5273. 7. Ribeiro, A.M., et al., Four beds pressure swing adsorption for hydrogen purification: Case of humid feed and activated carbon beds. AIChE Journal, 2009. 55(9): p. 2292-2302. 8. Yang, J. and C.-H. Lee, Adsorption dynamics of a layered bed PSA for H2 recovery from coke oven gas. AIChE Journal, 1998. 44(6): p. 1325-1334. 9. Yang, J., C.-H. Lee, and J.-W. Chang, Separation of Hydrogen Mixtures by a Two-Bed Pressure Swing Adsorption Process Using Zeolite 5A. Industrial & Engineering Chemistry Research, 1997. 36(7): p. 2789-2798. 10. Agarwal, A., L.T. Biegler, and S.E. Zitney, A superstructure-based optimal synthesis of PSA cycles for post-combustion CO2 capture. AIChE Journal, 2010. 56(7): p. 1813-1828. 11. Choi, W.-K., et al., Optimal operation of the pressure swing adsorption (PSA) process for CO2 recovery. Korean Journal of Chemical Engineering, 2003. 20(4): p. 617-623. 12. Chou, C.-T. and C.-Y. Chen, Carbon dioxide recovery by vacuum swing adsorption. Separation and Purification Technology, 2004. 39(1–2): p. 51-65. 13. Ishibashi, M., et al., Technology for removing carbon dioxide from power plant flue gas by the physical adsorption method. Energy Conversion and Management, 1996. 37(6–8): p. 929-933. 14. Kikkinides, E.S., R.T. Yang, and S.H. Cho, Concentration and recovery of carbon dioxide from flue gas by pressure swing adsorption. Industrial & Engineering Chemistry Research, 1993. 32(11): p. 2714-2720. 15. Ko, D., R. Siriwardane, and L.T. Biegler, Optimization of Pressure Swing Adsorption and Fractionated Vacuum Pressure Swing Adsorption Processes for CO2 Capture. Industrial & Engineering Chemistry Research, 2005. 44(21): p. 8084-8094. 16. Liu, Z., et al., Multi-bed Vacuum Pressure Swing Adsorption for carbon dioxide capture from flue gas. Separation and Purification Technology, 2011. 81(3): p. 307-317. 17. Mehrotra, A., A. Ebner, and J. Ritter, Arithmetic approach for complex PSA cycle scheduling. Adsorption, 2010. 16(3): p. 113-126.PDF Image | Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-fired

PDF Search Title:

Evaluating Pressure Swing Adsorption as a CO2 separation technique in coal-firedOriginal File Name Searched:

PSA-coal-fired-plants.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |