PDF Publication Title:

Text from PDF Page: 009

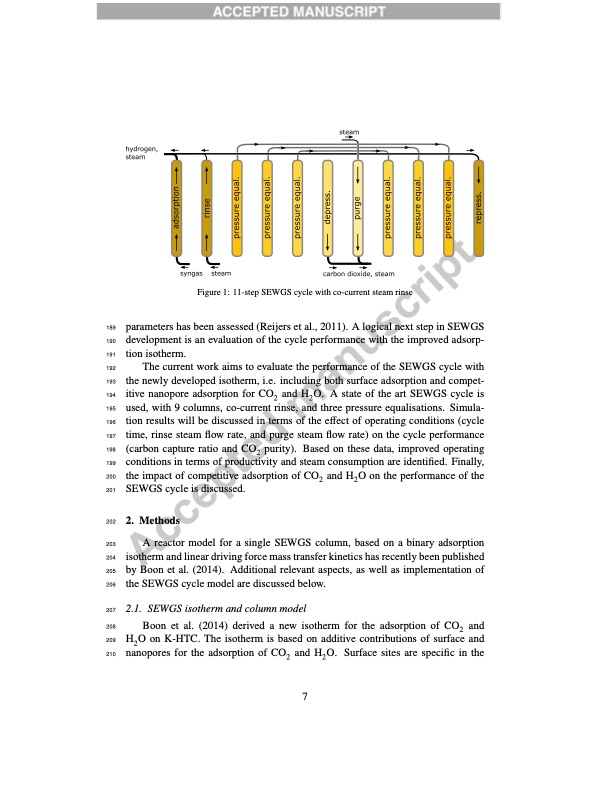

Figure 1: 11-step SEWGS cycle with co-current steam rinse 189 parameters has been assessed (Reijers et al., 2011). A logical next step in SEWGS 190 development is an evaluation of the cycle performance with the improved adsorp- 191 tion isotherm. 192 The current work aims to evaluate the performance of the SEWGS cycle with 193 the newly developed isotherm, i.e. including both surface adsorption and compet- 194 itive nanopore adsorption for CO2 and H2O. A state of the art SEWGS cycle is 195 used, with 9 columns, co-current rinse, and three pressure equalisations. Simula- 196 tion results will be discussed in terms of the effect of operating conditions (cycle 197 time, rinse steam flow rate, and purge steam flow rate) on the cycle performance 198 (carbon capture ratio and CO2 purity). Based on these data, improved operating 199 conditions in terms of productivity and steam consumption are identified. Finally, 200 the impact of competitive adsorption of CO2 and H2O on the performance of the 201 SEWGS cycle is discussed. 202 2. Methods 203 A reactor model for a single SEWGS column, based on a binary adsorption 204 isotherm and linear driving force mass transfer kinetics has recently been published 205 by Boon et al. (2014). Additional relevant aspects, as well as implementation of 206 the SEWGS cycle model are discussed below. 207 2.1. SEWGS isotherm and column model 208 Boon et al. (2014) derived a new isotherm for the adsorption of CO2 and 209 H2O on K-HTC. The isotherm is based on additive contributions of surface and 210 nanopores for the adsorption of CO2 and H2O. Surface sites are specific in the 7PDF Image | High-temperature pressure swing adsorption cycle design for sorption

PDF Search Title:

High-temperature pressure swing adsorption cycle design for sorptionOriginal File Name Searched:

high-temperature-pressure-swing-adsorption.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |