PDF Publication Title:

Text from PDF Page: 023

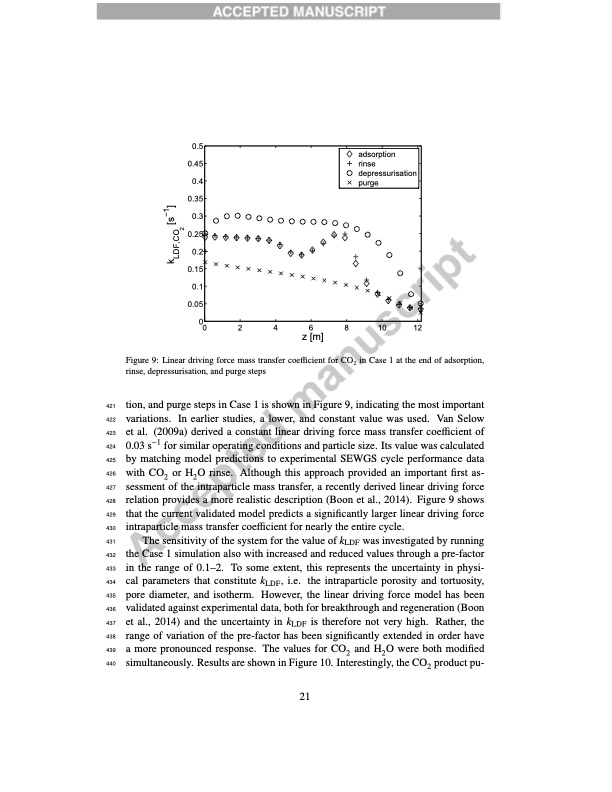

0.5 0.45 0.4 0.35 0.3 0.25 0.2 0.15 0.1 0.05 00 2 4 6 8 10 12 z [m] Figure 9: Linear driving force mass transfer coefficient for CO2 in Case 1 at the end of adsorption, rinse, depressurisation, and purge steps 421 tion, and purge steps in Case 1 is shown in Figure 9, indicating the most important 422 variations. In earlier studies, a lower, and constant value was used. Van Selow 423 et al. (2009a) derived a constant linear driving force mass transfer coefficient of 424 0.03 s−1 for similar operating conditions and particle size. Its value was calculated 425 by matching model predictions to experimental SEWGS cycle performance data 426 with CO2 or H2O rinse. Although this approach provided an important first as- 427 sessment of the intraparticle mass transfer, a recently derived linear driving force 428 relation provides a more realistic description (Boon et al., 2014). Figure 9 shows 429 that the current validated model predicts a significantly larger linear driving force 430 intraparticle mass transfer coefficient for nearly the entire cycle. 431 The sensitivity of the system for the value of kLDF was investigated by running 432 the Case 1 simulation also with increased and reduced values through a pre-factor 433 in the range of 0.1–2. To some extent, this represents the uncertainty in physi- 434 cal parameters that constitute kLDF, i.e. the intraparticle porosity and tortuosity, 435 pore diameter, and isotherm. However, the linear driving force model has been 436 validated against experimental data, both for breakthrough and regeneration (Boon 437 et al., 2014) and the uncertainty in kLDF is therefore not very high. Rather, the 438 range of variation of the pre-factor has been significantly extended in order have 439 a more pronounced response. The values for CO2 and H2O were both modified 440 simultaneously. Results are shown in Figure 10. Interestingly, the CO2 product pu- 21 adsorption rinse depressurisation purge kLDF,CO [s�1] 2PDF Image | High-temperature pressure swing adsorption cycle design for sorption

PDF Search Title:

High-temperature pressure swing adsorption cycle design for sorptionOriginal File Name Searched:

high-temperature-pressure-swing-adsorption.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |