PDF Publication Title:

Text from PDF Page: 111

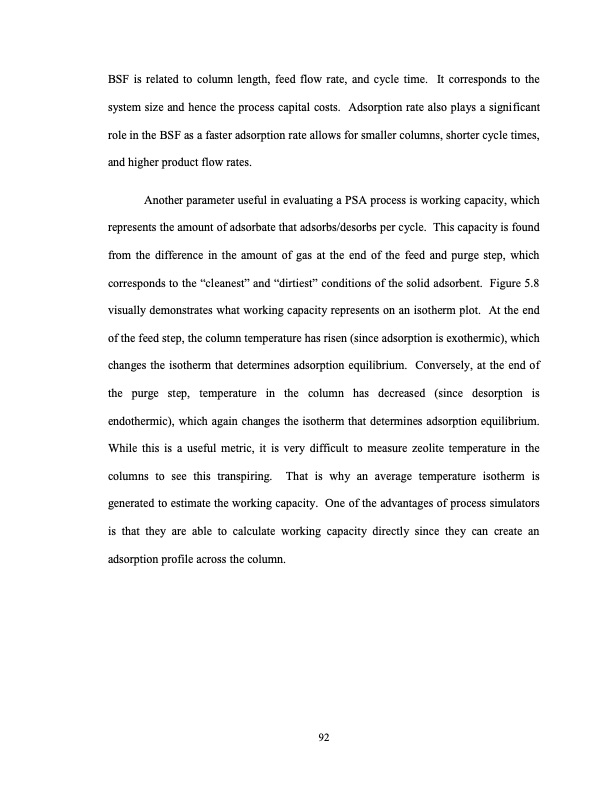

BSF is related to column length, feed flow rate, and cycle time. It corresponds to the system size and hence the process capital costs. Adsorption rate also plays a significant role in the BSF as a faster adsorption rate allows for smaller columns, shorter cycle times, and higher product flow rates. Another parameter useful in evaluating a PSA process is working capacity, which represents the amount of adsorbate that adsorbs/desorbs per cycle. This capacity is found from the difference in the amount of gas at the end of the feed and purge step, which corresponds to the “cleanest” and “dirtiest” conditions of the solid adsorbent. Figure 5.8 visually demonstrates what working capacity represents on an isotherm plot. At the end of the feed step, the column temperature has risen (since adsorption is exothermic), which changes the isotherm that determines adsorption equilibrium. Conversely, at the end of the purge step, temperature in the column has decreased (since desorption is endothermic), which again changes the isotherm that determines adsorption equilibrium. While this is a useful metric, it is very difficult to measure zeolite temperature in the columns to see this transpiring. That is why an average temperature isotherm is generated to estimate the working capacity. One of the advantages of process simulators is that they are able to calculate working capacity directly since they can create an adsorption profile across the column. 92PDF Image | LIMITS OF SMALL SCALE PRESSURE SWING ADSORPTION

PDF Search Title:

LIMITS OF SMALL SCALE PRESSURE SWING ADSORPTIONOriginal File Name Searched:

Limits of Small Scale PSA_Aaron Moran.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |