PDF Publication Title:

Text from PDF Page: 005

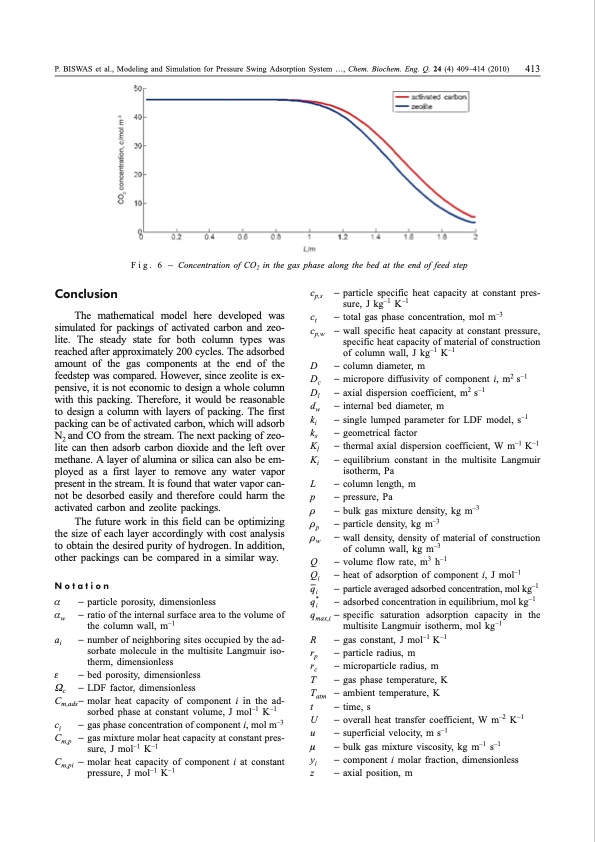

P. BISWAS et al., Modeling and Simulation for Pressure Swing Adsorption System ..., Chem. Biochem. Eng. Q. 24 (4) 409–414 (2010) 413 F i g . 6 – Concentration of CO2 in the gas phase along the bed at the end of feed step Conclusion The mathematical model here developed was simulated for packings of activated carbon and zeo- lite. The steady state for both column types was reached after approximately 200 cycles. The adsorbed amount of the gas components at the end of the feedstep was compared. However, since zeolite is ex- pensive, it is not economic to design a whole column with this packing. Therefore, it would be reasonable to design a column with layers of packing. The first packing can be of activated carbon, which will adsorb N2 and CO from the stream. The next packing of zeo- lite can then adsorb carbon dioxide and the left over methane. A layer of alumina or silica can also be em- ployed as a first layer to remove any water vapor present in the stream. It is found that water vapor can- not be desorbed easily and therefore could harm the activated carbon and zeolite packings. The future work in this field can be optimizing the size of each layer accordingly with cost analysis to obtain the desired purity of hydrogen. In addition, other packings can be compared in a similar way. Notation cp,s - ct - cp,w - D - Dc - Dl - dw - k - i ks - Kl - Ki - L - p - r - rp - rw - Q - Qi - qi - q*i - qmax,i - R - rp - rc - T - Tatm - t - U - u - m - yi - z - particle specific heat capacity at constant pres- sure, J kg–1 K–1 total gas phase concentration, mol m–3 wall specific heat capacity at constant pressure, specific heat capacity of material of construction of column wall, J kg–1 K–1 column diameter, m micropore diffusivity of component i, m2 s–1 axial dispersion coefficient, m2 s–1 internal bed diameter, m single lumped parameter for LDF model, s–1 geometrical factor thermal axial dispersion coefficient, W m–1 K–1 equilibrium constant in the multisite Langmuir isotherm, Pa column length, m pressure, Pa bulk gas mixture density, kg m–3 particle density, kg m–3 wall density, density of material of construction of column wall, kg m–3 volume flow rate, m3 h–1 heat of adsorption of component i, J mol–1 particle averaged adsorbed concentration, mol kg–1 adsorbed concentration in equilibrium, mol kg–1 specific saturation adsorption capacity in the multisite Langmuir isotherm, mol kg–1 gas constant, J mol–1 K–1 particle radius, m microparticle radius, m gas phase temperature, K ambient temperature, K time, s overall heat transfer coefficient, W m–2 K–1 superficial velocity, m s–1 bulk gas mixture viscosity, kg m–1 s–1 component i molar fraction, dimensionless axial position, m a - aw - ai - e - Wc - Cm,ads- ci - Cm,p - Cm,pi - particle porosity, dimensionless ratio of the internal surface area to the volume of the column wall, m–1 number of neighboring sites occupied by the ad- sorbate molecule in the multisite Langmuir iso- therm, dimensionless bed porosity, dimensionless LDF factor, dimensionless molar heat capacity of component i in the ad- sorbed phase at constant volume, J mol–1 K–1 gas phase concentration of component i, mol m–3 gas mixture molar heat capacity at constant pres- sure, J mol–1 K–1 molar heat capacity of component i at constant pressure, J mol–1 K–1PDF Image | Modeling and Simulation for Pressure Swing Adsorption System

PDF Search Title:

Modeling and Simulation for Pressure Swing Adsorption SystemOriginal File Name Searched:

Cabeq-2010-04-03.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |