PDF Publication Title:

Text from PDF Page: 007

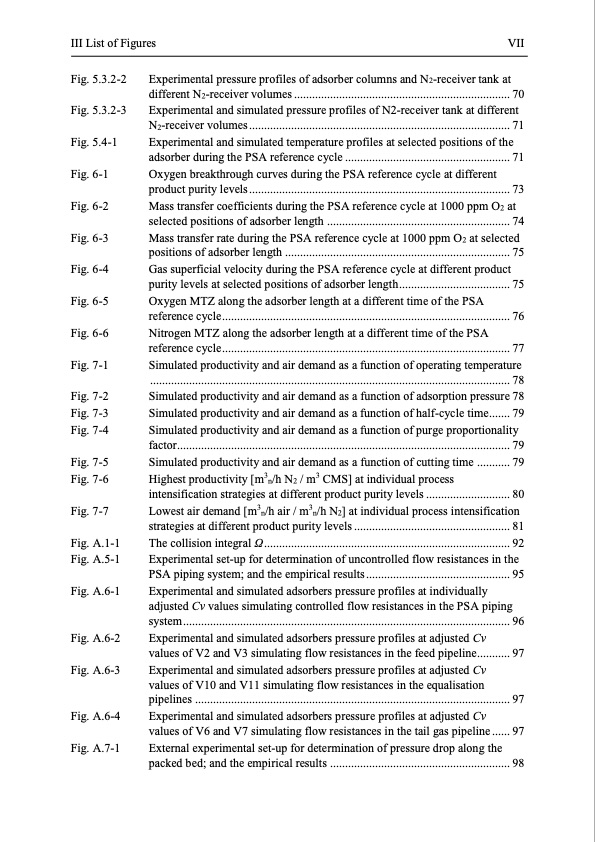

III List of Figures VII Fig. 5.3.2-2 Fig. 5.3.2-3 Fig. 5.4-1 Fig. 6-1 Fig. 6-2 Fig. 6-3 Fig. 6-4 Fig. 6-5 Fig. 6-6 Fig. 7-1 Fig. 7-2 Fig. 7-3 Fig. 7-4 Fig. 7-5 Fig. 7-6 Fig. 7-7 Fig. A.1-1 Fig. A.5-1 Fig. A.6-1 Fig. A.6-2 Fig. A.6-3 Fig. A.6-4 Fig. A.7-1 Experimental pressure profiles of adsorber columns and N2-receiver tank at different N2-receiver volumes ........................................................................ 70 Experimental and simulated pressure profiles of N2-receiver tank at different N2-receiver volumes ....................................................................................... 71 Experimental and simulated temperature profiles at selected positions of the adsorber during the PSA reference cycle ....................................................... 71 Oxygen breakthrough curves during the PSA reference cycle at different product purity levels....................................................................................... 73 Mass transfer coefficients during the PSA reference cycle at 1000 ppm O2 at selected positions of adsorber length ............................................................. 74 Mass transfer rate during the PSA reference cycle at 1000 ppm O2 at selected positions of adsorber length ........................................................................... 75 Gas superficial velocity during the PSA reference cycle at different product purity levels at selected positions of adsorber length..................................... 75 Oxygen MTZ along the adsorber length at a different time of the PSA reference cycle................................................................................................ 76 Nitrogen MTZ along the adsorber length at a different time of the PSA reference cycle................................................................................................ 77 Simulated productivity and air demand as a function of operating temperature ........................................................................................................................ 78 Simulated productivity and air demand as a function of adsorption pressure 78 Simulated productivity and air demand as a function of half-cycle time....... 79 Simulated productivity and air demand as a function of purge proportionality factor............................................................................................................... 79 Simulated productivity and air demand as a function of cutting time ........... 79 Highest productivity [m3n/h N2 / m3 CMS] at individual process intensification strategies at different product purity levels ............................ 80 Lowest air demand [m3n/h air / m3n/h N2] at individual process intensification strategies at different product purity levels .................................................... 81 The collision integral Ω.................................................................................. 92 Experimental set-up for determination of uncontrolled flow resistances in the PSA piping system; and the empirical results ................................................ 95 Experimental and simulated adsorbers pressure profiles at individually adjusted Cv values simulating controlled flow resistances in the PSA piping system............................................................................................................. 96 Experimental and simulated adsorbers pressure profiles at adjusted Cv values of V2 and V3 simulating flow resistances in the feed pipeline........... 97 Experimental and simulated adsorbers pressure profiles at adjusted Cv values of V10 and V11 simulating flow resistances in the equalisation pipelines ......................................................................................................... 97 Experimental and simulated adsorbers pressure profiles at adjusted Cv values of V6 and V7 simulating flow resistances in the tail gas pipeline ...... 97 External experimental set-up for determination of pressure drop along the packed bed; and the empirical results ............................................................ 98PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |