PDF Publication Title:

Text from PDF Page: 011

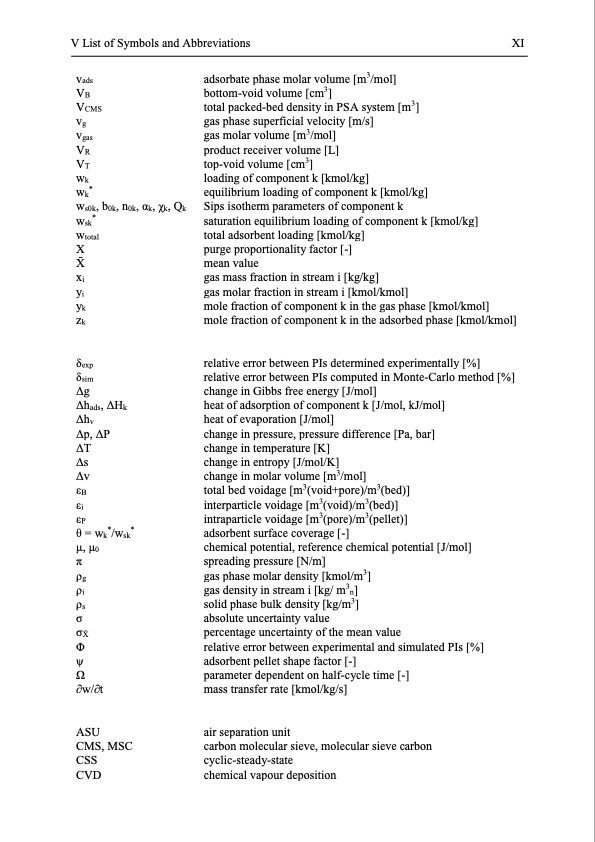

V List of Symbols and Abbreviations XI vads VB VCMS vg vgas VR VT wk wk* ws0k, b0k, n0k, αk, χk, Qk wsk* wtotal X X̄ xi yi yk zk δexp δsim Δg Δhads, ΔHk Δhv Δp, ΔP ΔT Δs Δv εB εi εP θ = wk*/wsk* μ, μ0 π ρg ρi ρs σ σX̄ Φ ψ Ω ∂w/∂t ASU CMS, MSC CSS CVD adsorbate phase molar volume [m3/mol] bottom-void volume [cm3] total packed-bed density in PSA system [m3] gas phase superficial velocity [m/s] gas molar volume [m3/mol] product receiver volume [L] top-void volume [cm3] loading of component k [kmol/kg] equilibrium loading of component k [kmol/kg] Sips isotherm parameters of component k saturation equilibrium loading of component k [kmol/kg] total adsorbent loading [kmol/kg] purge proportionality factor [-] mean value gas mass fraction in stream i [kg/kg] gas molar fraction in stream i [kmol/kmol] mole fraction of component k in the gas phase [kmol/kmol] mole fraction of component k in the adsorbed phase [kmol/kmol] relative error between PIs determined experimentally [%] relative error between PIs computed in Monte-Carlo method [%] change in Gibbs free energy [J/mol] heat of adsorption of component k [J/mol, kJ/mol] heat of evaporation [J/mol] change in pressure, pressure difference [Pa, bar] change in temperature [K] change in entropy [J/mol/K] change in molar volume [m3/mol] total bed voidage [m3(void+pore)/m3(bed)] interparticle voidage [m3(void)/m3(bed)] intraparticle voidage [m3(pore)/m3(pellet)] adsorbent surface coverage [-] chemical potential, reference chemical potential [J/mol] spreading pressure [N/m] gas phase molar density [kmol/m3] gas density in stream i [kg/ m3n] solid phase bulk density [kg/m3] absolute uncertainty value percentage uncertainty of the mean value relative error between experimental and simulated PIs [%] adsorbent pellet shape factor [-] parameter dependent on half-cycle time [-] mass transfer rate [kmol/kg/s] air separation unit carbon molecular sieve, molecular sieve carbon cyclic-steady-state chemical vapour depositionPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |