PDF Publication Title:

Text from PDF Page: 034

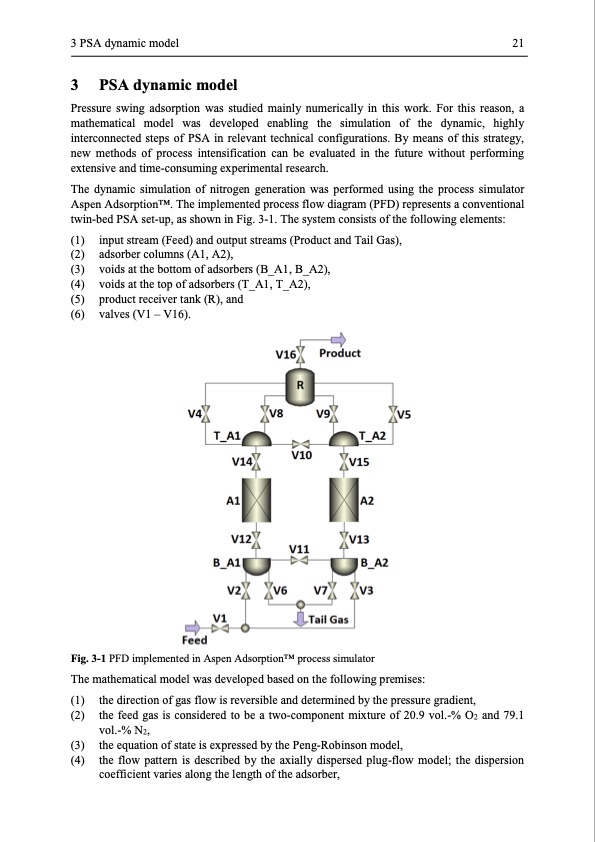

3 PSA dynamic model 21 3 PSA dynamic model Pressure swing adsorption was studied mainly numerically in this work. For this reason, a mathematical model was developed enabling the simulation of the dynamic, highly interconnected steps of PSA in relevant technical configurations. By means of this strategy, new methods of process intensification can be evaluated in the future without performing extensive and time-consuming experimental research. The dynamic simulation of nitrogen generation was performed using the process simulator Aspen AdsorptionTM. The implemented process flow diagram (PFD) represents a conventional twin-bed PSA set-up, as shown in Fig. 3-1. The system consists of the following elements: (1) input stream (Feed) and output streams (Product and Tail Gas), (2) adsorber columns (A1, A2), (3) voids at the bottom of adsorbers (B_A1, B_A2), (4) voids at the top of adsorbers (T_A1, T_A2), (5) product receiver tank (R), and (6) valves (V1 – V16). Fig. 3-1 PFD implemented in Aspen AdsorptionTM process simulator The mathematical model was developed based on the following premises: (1) the direction of gas flow is reversible and determined by the pressure gradient, (2) the feed gas is considered to be a two-component mixture of 20.9 vol.-% O2 and 79.1 vol.-% N2, (3) the equation of state is expressed by the Peng-Robinson model, (4) the flow pattern is described by the axially dispersed plug-flow model; the dispersion coefficient varies along the length of the adsorber,PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |