PDF Publication Title:

Text from PDF Page: 057

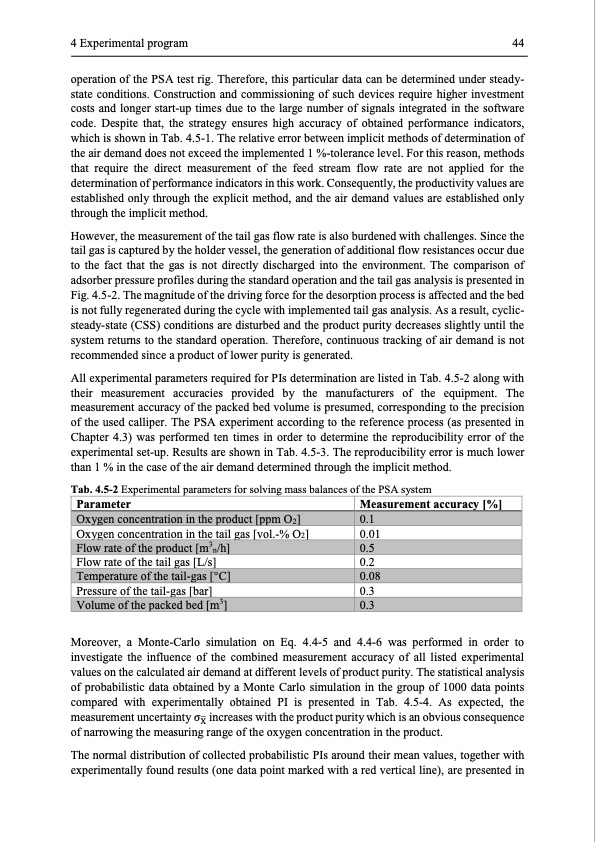

4 Experimental program 44 operation of the PSA test rig. Therefore, this particular data can be determined under steady- state conditions. Construction and commissioning of such devices require higher investment costs and longer start-up times due to the large number of signals integrated in the software code. Despite that, the strategy ensures high accuracy of obtained performance indicators, which is shown in Tab. 4.5-1. The relative error between implicit methods of determination of the air demand does not exceed the implemented 1 %-tolerance level. For this reason, methods that require the direct measurement of the feed stream flow rate are not applied for the determination of performance indicators in this work. Consequently, the productivity values are established only through the explicit method, and the air demand values are established only through the implicit method. However, the measurement of the tail gas flow rate is also burdened with challenges. Since the tail gas is captured by the holder vessel, the generation of additional flow resistances occur due to the fact that the gas is not directly discharged into the environment. The comparison of adsorber pressure profiles during the standard operation and the tail gas analysis is presented in Fig. 4.5-2. The magnitude of the driving force for the desorption process is affected and the bed is not fully regenerated during the cycle with implemented tail gas analysis. As a result, cyclic- steady-state (CSS) conditions are disturbed and the product purity decreases slightly until the system returns to the standard operation. Therefore, continuous tracking of air demand is not recommended since a product of lower purity is generated. All experimental parameters required for PIs determination are listed in Tab. 4.5-2 along with their measurement accuracies provided by the manufacturers of the equipment. The measurement accuracy of the packed bed volume is presumed, corresponding to the precision of the used calliper. The PSA experiment according to the reference process (as presented in Chapter 4.3) was performed ten times in order to determine the reproducibility error of the experimental set-up. Results are shown in Tab. 4.5-3. The reproducibility error is much lower than 1 % in the case of the air demand determined through the implicit method. Tab. 4.5-2 Experimental parameters for solving mass balances of the PSA system Parameter Oxygen concentration in the tail gas [vol.-% O2] Flow rate of the tail gas [L/s] Pressure of the tail-gas [bar] Measurement accuracy [%] 0.01 0.2 0.3 Oxygen concentration in the product [ppm O2] 0.1 Flow rate of the product [m3n/h] 0.5 Temperature of the tail-gas [°C] 0.08 Volume of the packed bed [m3] 0.3 Moreover, a Monte-Carlo simulation on Eq. 4.4-5 and 4.4-6 was performed in order to investigate the influence of the combined measurement accuracy of all listed experimental values on the calculated air demand at different levels of product purity. The statistical analysis of probabilistic data obtained by a Monte Carlo simulation in the group of 1000 data points compared with experimentally obtained PI is presented in Tab. 4.5-4. As expected, the measurement uncertainty σ̅ increases with the product purity which is an obvious consequence X of narrowing the measuring range of the oxygen concentration in the product. The normal distribution of collected probabilistic PIs around their mean values, together with experimentally found results (one data point marked with a red vertical line), are presented inPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |