PDF Publication Title:

Text from PDF Page: 059

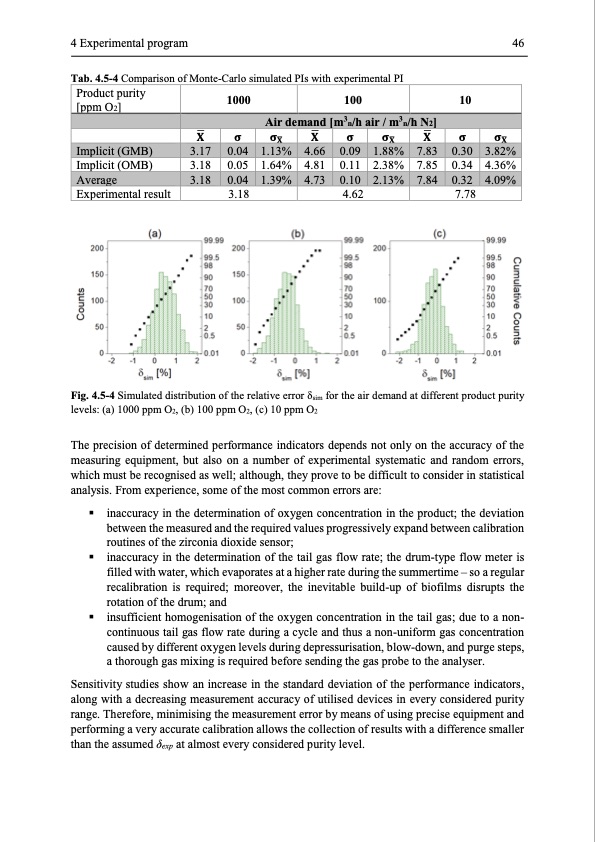

4 Experimental program 46 Tab. 4.5-4 Comparison of Monte-Carlo simulated PIs with experimental PI Product purity [ppm O2] Implicit (OMB) Experimental result 1000 100 10 Air demand [m3n/h air / m3n/h N2] ̅̅̅ 𝐗 𝛔 𝛔̅ 𝐗 𝛔 𝛔̅ 𝐗 𝛔 𝛔̅ 𝐗𝐗𝐗 3.18 0.05 1.64% 4.81 0.11 2.38% 7.85 0.34 4.36% 3.18 4.62 7.78 Implicit (GMB) 3.17 0.04 1.13% 4.66 0.09 1.88% 7.83 0.30 3.82% Average 3.18 0.04 1.39% 4.73 0.10 2.13% 7.84 0.32 4.09% Fig. 4.5-4 Simulated distribution of the relative error δsim for the air demand at different product purity levels: (a) 1000 ppm O2, (b) 100 ppm O2, (c) 10 ppm O2 The precision of determined performance indicators depends not only on the accuracy of the measuring equipment, but also on a number of experimental systematic and random errors, which must be recognised as well; although, they prove to be difficult to consider in statistical analysis. From experience, some of the most common errors are: ▪ inaccuracy in the determination of oxygen concentration in the product; the deviation between the measured and the required values progressively expand between calibration routines of the zirconia dioxide sensor; ▪ inaccuracy in the determination of the tail gas flow rate; the drum-type flow meter is filled with water, which evaporates at a higher rate during the summertime – so a regular recalibration is required; moreover, the inevitable build-up of biofilms disrupts the rotation of the drum; and ▪ insufficient homogenisation of the oxygen concentration in the tail gas; due to a non- continuous tail gas flow rate during a cycle and thus a non-uniform gas concentration caused by different oxygen levels during depressurisation, blow-down, and purge steps, a thorough gas mixing is required before sending the gas probe to the analyser. Sensitivity studies show an increase in the standard deviation of the performance indicators, along with a decreasing measurement accuracy of utilised devices in every considered purity range. Therefore, minimising the measurement error by means of using precise equipment and performing a very accurate calibration allows the collection of results with a difference smaller than the assumed δexp at almost every considered purity level.PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |