PDF Publication Title:

Text from PDF Page: 064

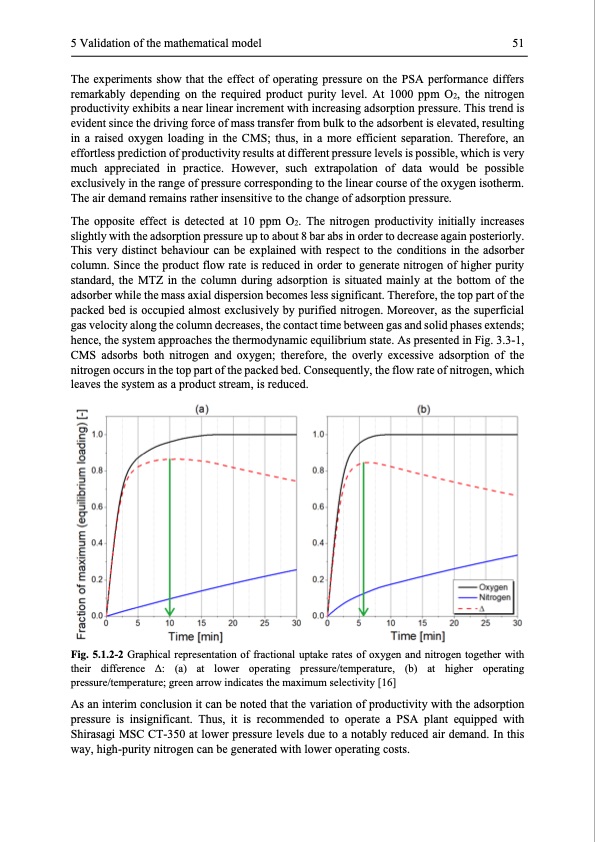

5 Validation of the mathematical model 51 The experiments show that the effect of operating pressure on the PSA performance differs remarkably depending on the required product purity level. At 1000 ppm O2, the nitrogen productivity exhibits a near linear increment with increasing adsorption pressure. This trend is evident since the driving force of mass transfer from bulk to the adsorbent is elevated, resulting in a raised oxygen loading in the CMS; thus, in a more efficient separation. Therefore, an effortless prediction of productivity results at different pressure levels is possible, which is very much appreciated in practice. However, such extrapolation of data would be possible exclusively in the range of pressure corresponding to the linear course of the oxygen isotherm. The air demand remains rather insensitive to the change of adsorption pressure. The opposite effect is detected at 10 ppm O2. The nitrogen productivity initially increases slightly with the adsorption pressure up to about 8 bar abs in order to decrease again posteriorly. This very distinct behaviour can be explained with respect to the conditions in the adsorber column. Since the product flow rate is reduced in order to generate nitrogen of higher purity standard, the MTZ in the column during adsorption is situated mainly at the bottom of the adsorber while the mass axial dispersion becomes less significant. Therefore, the top part of the packed bed is occupied almost exclusively by purified nitrogen. Moreover, as the superficial gas velocity along the column decreases, the contact time between gas and solid phases extends; hence, the system approaches the thermodynamic equilibrium state. As presented in Fig. 3.3-1, CMS adsorbs both nitrogen and oxygen; therefore, the overly excessive adsorption of the nitrogen occurs in the top part of the packed bed. Consequently, the flow rate of nitrogen, which leaves the system as a product stream, is reduced. Fig. 5.1.2-2 Graphical representation of fractional uptake rates of oxygen and nitrogen together with their difference Δ: (a) at lower operating pressure/temperature, (b) at higher operating pressure/temperature; green arrow indicates the maximum selectivity [16] As an interim conclusion it can be noted that the variation of productivity with the adsorption pressure is insignificant. Thus, it is recommended to operate a PSA plant equipped with Shirasagi MSC CT-350 at lower pressure levels due to a notably reduced air demand. In this way, high-purity nitrogen can be generated with lower operating costs.PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |