PDF Publication Title:

Text from PDF Page: 067

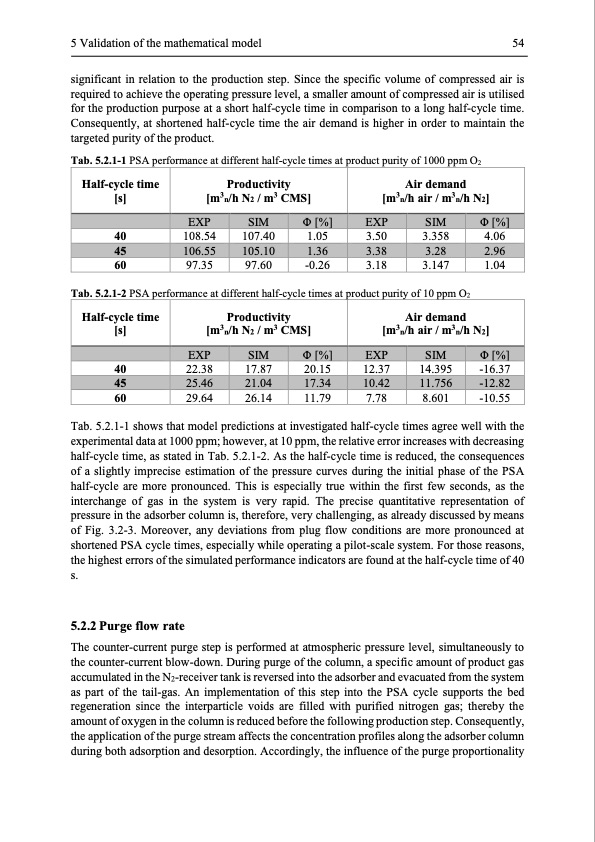

5 Validation of the mathematical model 54 significant in relation to the production step. Since the specific volume of compressed air is required to achieve the operating pressure level, a smaller amount of compressed air is utilised for the production purpose at a short half-cycle time in comparison to a long half-cycle time. Consequently, at shortened half-cycle time the air demand is higher in order to maintain the targeted purity of the product. Tab. 5.2.1-1 PSA performance at different half-cycle times at product purity of 1000 ppm O2 40 108.54 107.40 1.05 3.50 3.358 4.06 60 97.35 97.60 -0.26 3.18 3.147 1.04 Tab. 5.2.1-2 PSA performance at different half-cycle times at product purity of 10 ppm O2 Half-cycle time [s] Productivity [m3n/h N2 / m3 CMS] Air demand [m3n/h air / m3n/h N2] EXP SIM Φ [%] EXP SIM Φ [%] 45 106.55 105.10 1.36 3.38 3.28 2.96 Half-cycle time [s] Productivity [m3n/h N2 / m3 CMS] Air demand [m3n/h air / m3n/h N2] EXP SIM Φ [%] EXP SIM Φ [%] 40 22.38 17.87 20.15 12.37 14.395 60 29.64 26.14 11.79 7.78 8.601 -16.37 -10.55 45 25.46 21.04 17.34 10.42 11.756 -12.82 Tab. 5.2.1-1 shows that model predictions at investigated half-cycle times agree well with the experimental data at 1000 ppm; however, at 10 ppm, the relative error increases with decreasing half-cycle time, as stated in Tab. 5.2.1-2. As the half-cycle time is reduced, the consequences of a slightly imprecise estimation of the pressure curves during the initial phase of the PSA half-cycle are more pronounced. This is especially true within the first few seconds, as the interchange of gas in the system is very rapid. The precise quantitative representation of pressure in the adsorber column is, therefore, very challenging, as already discussed by means of Fig. 3.2-3. Moreover, any deviations from plug flow conditions are more pronounced at shortened PSA cycle times, especially while operating a pilot-scale system. For those reasons, the highest errors of the simulated performance indicators are found at the half-cycle time of 40 s. 5.2.2 Purge flow rate The counter-current purge step is performed at atmospheric pressure level, simultaneously to the counter-current blow-down. During purge of the column, a specific amount of product gas accumulated in the N2-receiver tank is reversed into the adsorber and evacuated from the system as part of the tail-gas. An implementation of this step into the PSA cycle supports the bed regeneration since the interparticle voids are filled with purified nitrogen gas; thereby the amount of oxygen in the column is reduced before the following production step. Consequently, the application of the purge stream affects the concentration profiles along the adsorber column during both adsorption and desorption. Accordingly, the influence of the purge proportionalityPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |