PDF Publication Title:

Text from PDF Page: 071

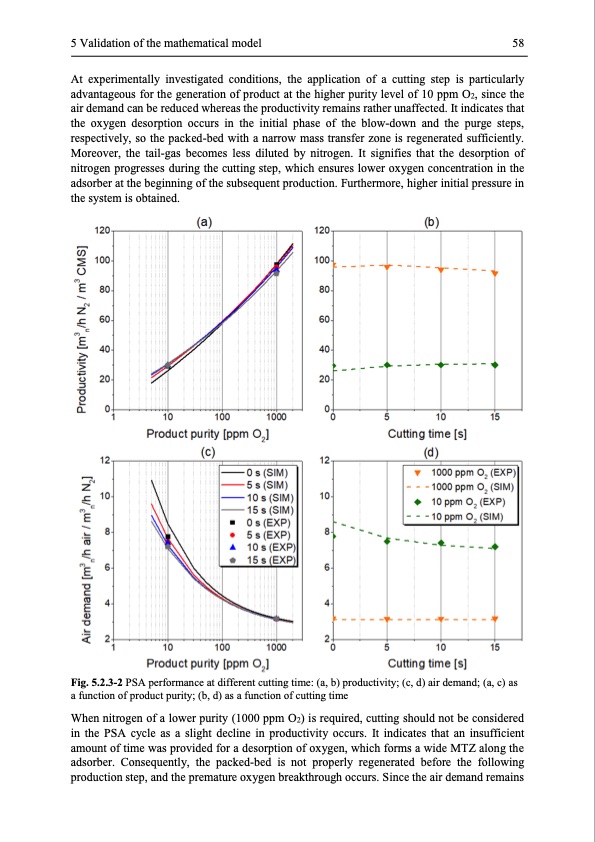

5 Validation of the mathematical model 58 At experimentally investigated conditions, the application of a cutting step is particularly advantageous for the generation of product at the higher purity level of 10 ppm O2, since the air demand can be reduced whereas the productivity remains rather unaffected. It indicates that the oxygen desorption occurs in the initial phase of the blow-down and the purge steps, respectively, so the packed-bed with a narrow mass transfer zone is regenerated sufficiently. Moreover, the tail-gas becomes less diluted by nitrogen. It signifies that the desorption of nitrogen progresses during the cutting step, which ensures lower oxygen concentration in the adsorber at the beginning of the subsequent production. Furthermore, higher initial pressure in the system is obtained. Fig. 5.2.3-2 PSA performance at different cutting time: (a, b) productivity; (c, d) air demand; (a, c) as a function of product purity; (b, d) as a function of cutting time When nitrogen of a lower purity (1000 ppm O2) is required, cutting should not be considered in the PSA cycle as a slight decline in productivity occurs. It indicates that an insufficient amount of time was provided for a desorption of oxygen, which forms a wide MTZ along the adsorber. Consequently, the packed-bed is not properly regenerated before the following production step, and the premature oxygen breakthrough occurs. Since the air demand remainsPDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |