PDF Publication Title:

Text from PDF Page: 073

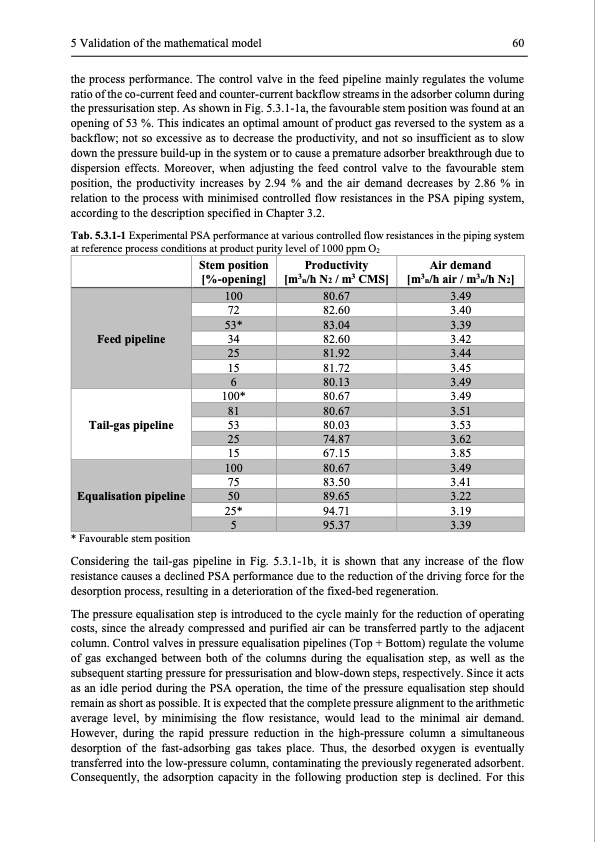

5 Validation of the mathematical model 60 the process performance. The control valve in the feed pipeline mainly regulates the volume ratio of the co-current feed and counter-current backflow streams in the adsorber column during the pressurisation step. As shown in Fig. 5.3.1-1a, the favourable stem position was found at an opening of 53 %. This indicates an optimal amount of product gas reversed to the system as a backflow; not so excessive as to decrease the productivity, and not so insufficient as to slow down the pressure build-up in the system or to cause a premature adsorber breakthrough due to dispersion effects. Moreover, when adjusting the feed control valve to the favourable stem position, the productivity increases by 2.94 % and the air demand decreases by 2.86 % in relation to the process with minimised controlled flow resistances in the PSA piping system, according to the description specified in Chapter 3.2. Tab. 5.3.1-1 Experimental PSA performance at various controlled flow resistances in the piping system at reference process conditions at product purity level of 1000 ppm O2 Feed pipeline 100 80.67 3.49 53* 83.04 3.39 25 81.92 3.44 6 80.13 3.49 81 80.67 3.51 Tail-gas pipeline * Favourable stem position Stem position [%-opening] 72 34 15 100* 53 15 75 25* Productivity [m3n/h N2 / m3 CMS] 82.60 82.60 81.72 80.67 80.03 67.15 83.50 94.71 Air demand [m3n/h air / m3n/h N2] 3.40 3.42 3.45 3.49 3.53 3.85 3.41 3.19 25 74.87 3.62 50 89.65 3.22 Equalisation pipeline 100 Considering the tail-gas pipeline in Fig. 5.3.1-1b, it is shown that any increase of the flow resistance causes a declined PSA performance due to the reduction of the driving force for the desorption process, resulting in a deterioration of the fixed-bed regeneration. The pressure equalisation step is introduced to the cycle mainly for the reduction of operating costs, since the already compressed and purified air can be transferred partly to the adjacent column. Control valves in pressure equalisation pipelines (Top + Bottom) regulate the volume of gas exchanged between both of the columns during the equalisation step, as well as the subsequent starting pressure for pressurisation and blow-down steps, respectively. Since it acts as an idle period during the PSA operation, the time of the pressure equalisation step should remain as short as possible. It is expected that the complete pressure alignment to the arithmetic average level, by minimising the flow resistance, would lead to the minimal air demand. However, during the rapid pressure reduction in the high-pressure column a simultaneous desorption of the fast-adsorbing gas takes place. Thus, the desorbed oxygen is eventually transferred into the low-pressure column, contaminating the previously regenerated adsorbent. Consequently, the adsorption capacity in the following production step is declined. For this 80.67 3.49 5 95.37 3.39PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |