PDF Publication Title:

Text from PDF Page: 082

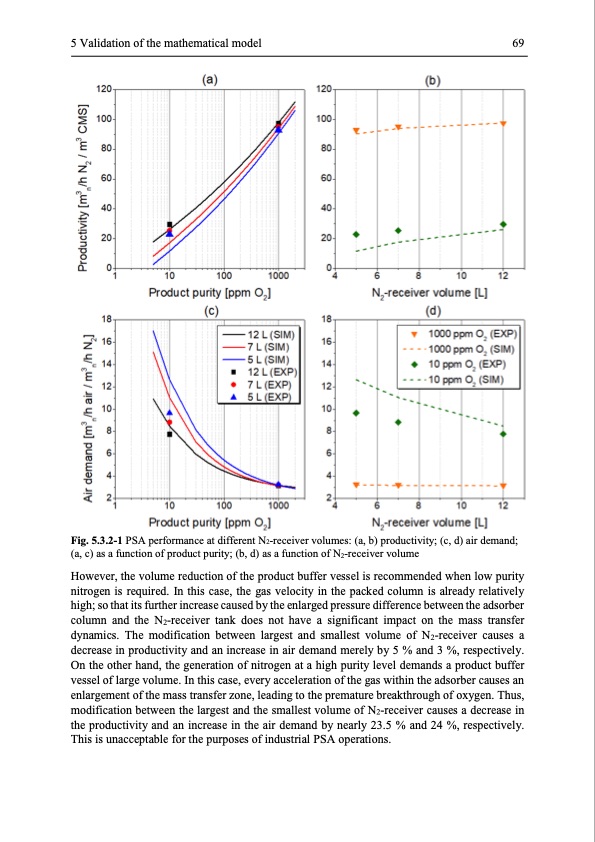

5 Validation of the mathematical model 69 Fig. 5.3.2-1 PSA performance at different N2-receiver volumes: (a, b) productivity; (c, d) air demand; (a, c) as a function of product purity; (b, d) as a function of N2-receiver volume However, the volume reduction of the product buffer vessel is recommended when low purity nitrogen is required. In this case, the gas velocity in the packed column is already relatively high; so that its further increase caused by the enlarged pressure difference between the adsorber column and the N2-receiver tank does not have a significant impact on the mass transfer dynamics. The modification between largest and smallest volume of N2-receiver causes a decrease in productivity and an increase in air demand merely by 5 % and 3 %, respectively. On the other hand, the generation of nitrogen at a high purity level demands a product buffer vessel of large volume. In this case, every acceleration of the gas within the adsorber causes an enlargement of the mass transfer zone, leading to the premature breakthrough of oxygen. Thus, modification between the largest and the smallest volume of N2-receiver causes a decrease in the productivity and an increase in the air demand by nearly 23.5 % and 24 %, respectively. This is unacceptable for the purposes of industrial PSA operations.PDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |