PDF Publication Title:

Text from PDF Page: 084

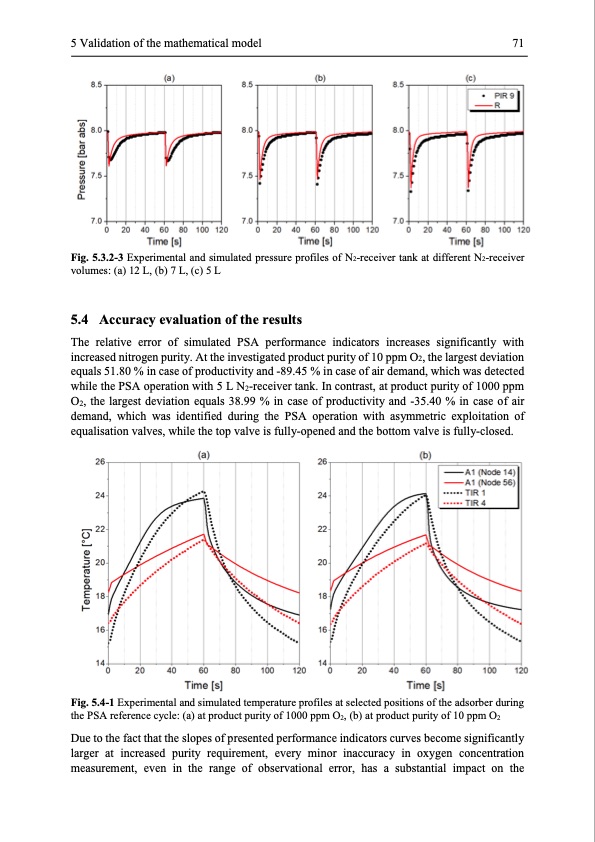

5 Validation of the mathematical model 71 Fig. 5.3.2-3 Experimental and simulated pressure profiles of N2-receiver tank at different N2-receiver volumes: (a) 12 L, (b) 7 L, (c) 5 L 5.4 Accuracy evaluation of the results The relative error of simulated PSA performance indicators increases significantly with increased nitrogen purity. At the investigated product purity of 10 ppm O2, the largest deviation equals 51.80 % in case of productivity and -89.45 % in case of air demand, which was detected while the PSA operation with 5 L N2-receiver tank. In contrast, at product purity of 1000 ppm O2, the largest deviation equals 38.99 % in case of productivity and -35.40 % in case of air demand, which was identified during the PSA operation with asymmetric exploitation of equalisation valves, while the top valve is fully-opened and the bottom valve is fully-closed. Fig. 5.4-1 Experimental and simulated temperature profiles at selected positions of the adsorber during the PSA reference cycle: (a) at product purity of 1000 ppm O2, (b) at product purity of 10 ppm O2 Due to the fact that the slopes of presented performance indicators curves become significantly larger at increased purity requirement, every minor inaccuracy in oxygen concentration measurement, even in the range of observational error, has a substantial impact on thePDF Image | Modelling and Simulation of Twin-Bed Pressure Swing Adsorption Plants

PDF Search Title:

Modelling and Simulation of Twin-Bed Pressure Swing Adsorption PlantsOriginal File Name Searched:

dissertation_marcinek.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |