PDF Publication Title:

Text from PDF Page: 032

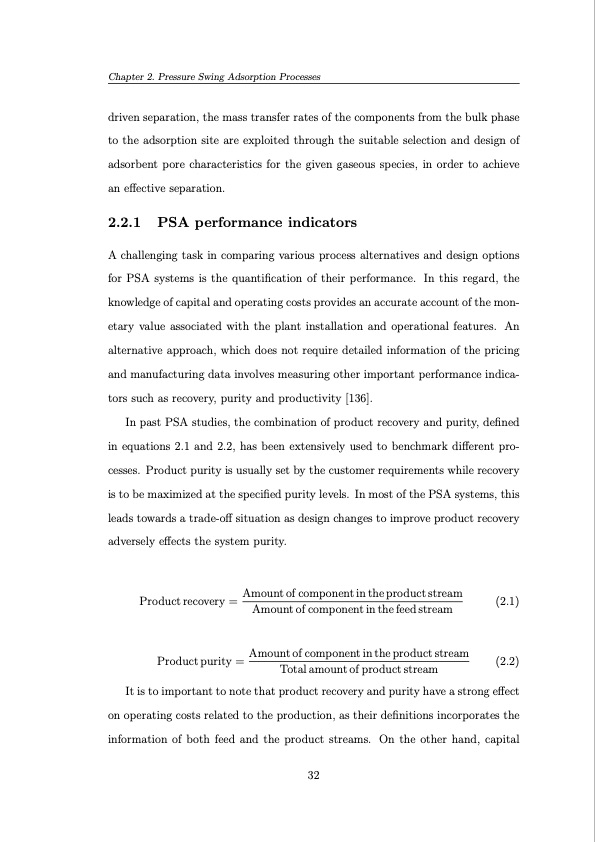

Chapter 2. Pressure Swing Adsorption Processes driven separation, the mass transfer rates of the components from the bulk phase to the adsorption site are exploited through the suitable selection and design of adsorbent pore characteristics for the given gaseous species, in order to achieve an effective separation. 2.2.1 PSA performance indicators A challenging task in comparing various process alternatives and design options for PSA systems is the quantification of their performance. In this regard, the knowledge of capital and operating costs provides an accurate account of the mon- etary value associated with the plant installation and operational features. An alternative approach, which does not require detailed information of the pricing and manufacturing data involves measuring other important performance indica- tors such as recovery, purity and productivity [136]. In past PSA studies, the combination of product recovery and purity, defined in equations 2.1 and 2.2, has been extensively used to benchmark different pro- cesses. Product purity is usually set by the customer requirements while recovery is to be maximized at the specified purity levels. In most of the PSA systems, this leads towards a trade-off situation as design changes to improve product recovery adversely effects the system purity. Product recovery = Amount of component in the product stream (2.1) Amount of component in the feed stream Product purity = Amount of component in the product stream (2.2) Total amount of product stream It is to important to note that product recovery and purity have a strong effect on operating costs related to the production, as their definitions incorporates the information of both feed and the product streams. On the other hand, capital 32PDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |